Safety

Comments: No Comments

Safe + Sound Week

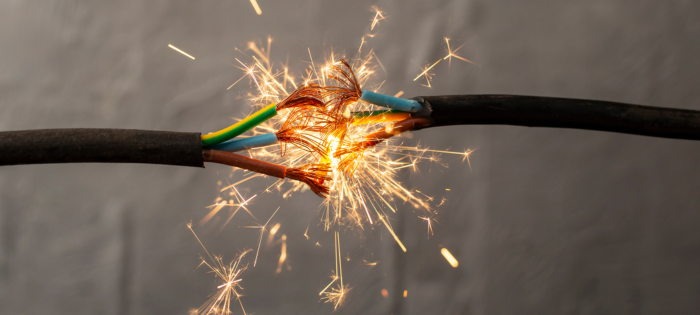

Electrical safety issues have been among the top findings in the Occupational Safety and Health Administration (OSHA) compliance audits KTL has conducted over the past year. Many workers are unaware of the potential electrical hazards present in their work environment when completing tasks that involve electricity. As such, they end up working in either unsafe conditions (e.g., poorly maintained/deteriorating equipment) or unsafe work practices (e.g., using conductive tools, not de-energizing prior to work)—or both. The result can be an OSHA finding or worse, including electrocution, electric shocks and burns, injury from exposure to arcing, and fire from faulty electrical equipment or installations.

Electrical Safety Standards

OSHA and National Fire Protection Association (NFPA) electrical safety regulations are complex. OSHA actually has several standards that address electrical safety. The most notable for general industry is 29 CFR 1910 Subpart S, which is broken into sections on design safety standards, safety-related work practices, safety-related maintenance requirements, and safety requirements for special equipment. If you have electrical equipment, at least some of OSHA’s electrical requirements will apply.

NFPA 70E supports the OSHA standard and fills in gaps, particularly related to qualified workers and hazard assessments. NFPA states that an Electrical Safety Program should develop a risk assessment procedure that outlines processes to identify hazards, assess risks, and implement controls before work begins. NFPA 70E is revised every three years.

Common Electrical Hazards

Electrical energy remains one of the most serious health hazards in the workplace, which is why all workers need to understand the dangers of electricity and how to take proper precautions. The following are the most common electrical safety gaps identified in KTL’s safety audits over the past year:

- Misused equipment. If electrical equipment is not used as designed or according to manufacturers’ instructions, safety features are not reliable.

- Damaged or defective electrical equipment is damaged or defective. When electrical panels, power disconnects, or any other electrical equipment in use at the site is not properly maintained, it can fall into disrepair. If electrical equipment is damaged, defective, or missing components, this may cause unintended contact with electrical components and lead to injury.

- Improperly used extension and flexible cords. Cords are subject to damage. Normal wear-and-tear can loosen or expose wires. In addition, employees do not always use the right type of cord for the intended usage and tend to repair and reuse cords that should be retired.

- Lack of ground-fault protection. Daily use of electrical equipment may lead to wear-and-tear (e.g., insulation breaks, short circuits, and exposed wires). Without proper safeguards, deteriorating equipment can create a ground fault that may send electrical current through a worker’s body.

- Missing path to ground. If the power supply to the electrical equipment is not grounded or the path is broken, fault current may travel through a worker’s body.

Creating Your Program

To eliminate these electrical hazards and their associated risks, it is important for any organization with electrical equipment to develop a written Electrical Safety Program, train employees, implement and enforce safe work practices, and regularly verify the Electrical Safety Program’s effectiveness.

Written Electrical Safety Program

A written Electrical Safety Program identifies the possible electrical hazards and outlines the procedures and controls required to effectively eliminate or engineer them out. Development of the Electrical Safety Program should be preceded by an electrical safety hazard assessment that systematically identifies electrical hazards that may cause harm, evaluates how likely and severe the potential harm is, and determines methods to effectively eliminate or control the harm from happening (i.e., hazard controls).

The Electrical Safety Program should consider safety through design, electrical risk management programs, job observations, refresher training, personal protective equipment (PPE) and tools, auditing, and electrical incident investigations.

Employee Training

It is important to understand that electrical training is not a one size fits all. As a part of an effective Electrical Safety Program, organizations should identify the scope of the electrical work—and who is qualified to do it—and then ensure those workers who have not been trained do not do electrical work. OSHA puts workers into two categories: unqualified workers and Qualified Electrical Workers (QEWs).

- Unqualified workers are those employees who are not trained or permitted to work with live electrical components but may face risk of electric shock (above 50 volts). Unqualified workers must receive training on safety-related work practices that pertain to their job tasks and the inherent hazards of electricity (high voltage, arc flash, lack of guarding, etc.).

- According to OSHA, a QEW is one who has received training in and has demonstrated skills and knowledge in the construction and operation of electric equipment and installations and the hazards involved. Only QEWs are permitted to work on or near energized parts.They must have the skills and techniques to distinguish exposed energized parts from other parts of electric equipment and appropriate training on all electrical safety procedures.

Safe Practices and Conditions

Even with the best Electrical Safety Program possible, if an organization continues to implement unsafe conditions or unsafe work practices, electrical safety accidents will continue. The following list provides best practices for working safely with electrical equipment:

General Electrical Safety Principles

- Always assume that overhead lines and all wires are energized, even if they appear to be insulated.

- Never operate electrical equipment while standing in water.

- Do not use electrical equipment that shocks, smokes, smells, is damaged, or has burn marks.

- Train all workers appropriately.

Power Line Safety

- Contact utilities to identify buried power lines, look for power line indicators, and post warning signs.

- Stay at least 10 feet away from overhead power lines (unqualified workers).

- De-energize and ground lines when working near them.

- Use non-conductive wood or fiberglass ladders when working near power lines.

Tools and Equipment Condition

- Use only equipment that is approved to meet OSHA standards, including double-insulated tools and equipment.

- Visually inspect all electrical equipment prior to use and remove any equipment with frayed cords, cracked casings, missing ground prongs, etc. from service.

- Make sure any altered equipment is compliant.

- Continually audit tools and equipment available for use onsite.

Grounding and Bonding

- Ground all power supply systems, electrical circuits, electrical equipment, and exposed metal parts of equipment.

- In wet/damp locations, ensure electrical circuits or receptacles are equipped with a Ground-Fault Circuit Interrupter (GFCI).

- Use GFCIs on all 120-volt, single-phase, 15- and 20-ampere receptacles.

- Follow manufacturers’ recommended testing procedures for GFCI.

- Frequently inspect electrical systems to ensure the path to ground is continuous.

Cord and Plug Safety

- Use factory-assembled cord sets and 3-wire type extension cords marked with designation codes for hard or extra hard usage.

- Use only cords, connection devices, and fittings that are equipped with strain relief.

- Do not modify cords, repair cords with electrical tape, or use them incorrectly.

- Remove cords from receptacles by pulling on the plugs, not the cords.

- Continually inspect cords used onsite.

Lockout/Tagout (LOTO) and De-energization

- When possible, de-energize electrical circuits before doing any type of work according to proper LOTO procedures.

- Use lockout devices to prevent a circuit from becoming energized.

- Use an AC voltage tester to verify that the electrical power is off.

Verify Effectiveness

It is important to analyze the effectiveness of all electrical safety efforts, including electrical safety hazard assessments, the written Electrical Safety Program, and associated work procedures and equipment. Regular audits and inspections can help ensure work conditions and work practices protect employees and create a culture that understands and promotes the importance of electrical safety.

Building Safe Systems

Electrical safety encompasses many different elements and requires specialized qualifications and expertise to safely manage. As such, bringing in a second set of eyes to review and/or help build the right size Electrical Safety Plan for your facility can be helpful (or even necessary depending on in-house electrical capabilities). Relying on experts with not only electrical capabilities but also overall occupational safety understanding can help ensure you implement practical solutions—from compliance audits to customized electrical safety strategies—that integrate with your corporate Safety Program and operations and make your electrical systems as safe as they are efficient.