Drones 101: Applicability

This is the second article in Kestrel’s Drones 101 series.

As we move into this important new phase of everyday use of drone technology in the workplace, some questions may arise:

- How many drones are there operating in commercial space?

- Where are they being used?

- How are they being used to help operations?

Commercial Drone Operation

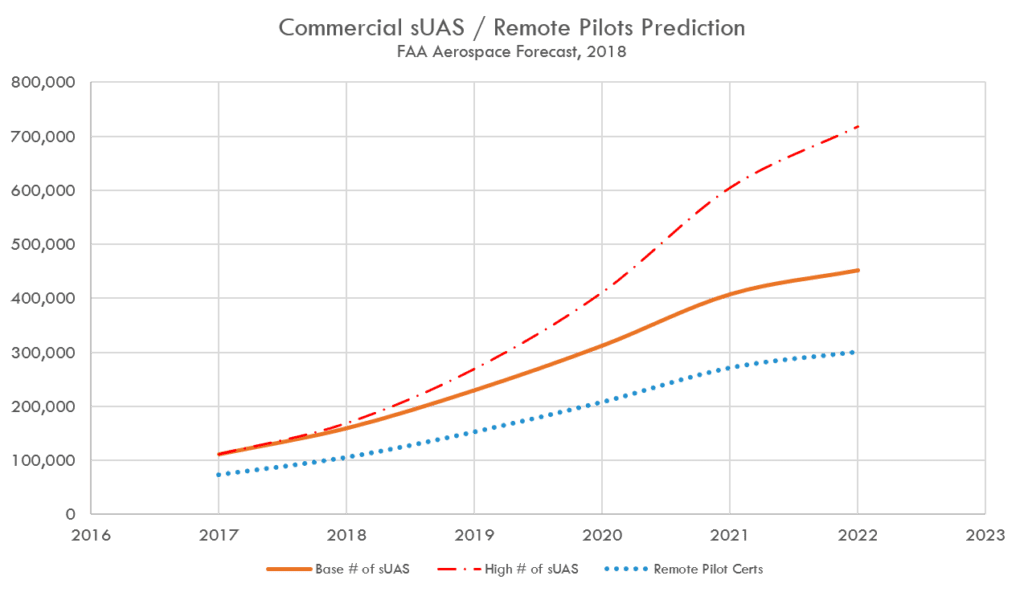

The chart below illustrates actual data from FAA’s aerospace forecast from this year. It highlights the phenomenal growth in drone use. The FAA projects that the commercial drone fleet is set to grow from over 110,000 in 2017 to over 450,000 by 2022 using its base, or most likely numbers. FAA’s high-end estimate predicts over 700,000 commercial drones in use by 2022. The number of remote pilots (indicated by the blue dotted line) is set to increase from 73,673 in 2017 to over 301,000 by 2022.

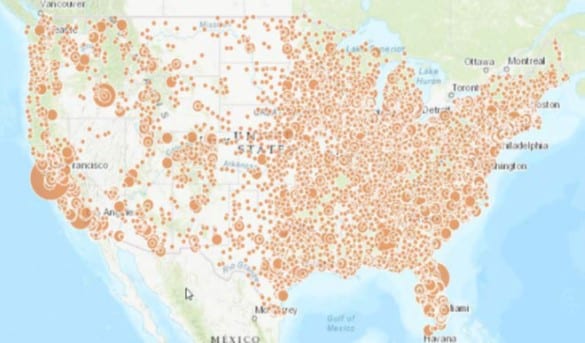

Further, the map below shows the distribution of registered commercial drones in the U.S. in 2017. The larger dots indicate a higher number of drones registered in that area. From this information you can see that commercial drones are popular and in use all over the country, not just in isolated pockets.

Further, the map below shows the distribution of registered commercial drones in the U.S. in 2017. The larger dots indicate a higher number of drones registered in that area. From this information you can see that commercial drones are popular and in use all over the country, not just in isolated pockets.

Typical Uses of Commercial sUAS

Typical Uses of Commercial sUAS

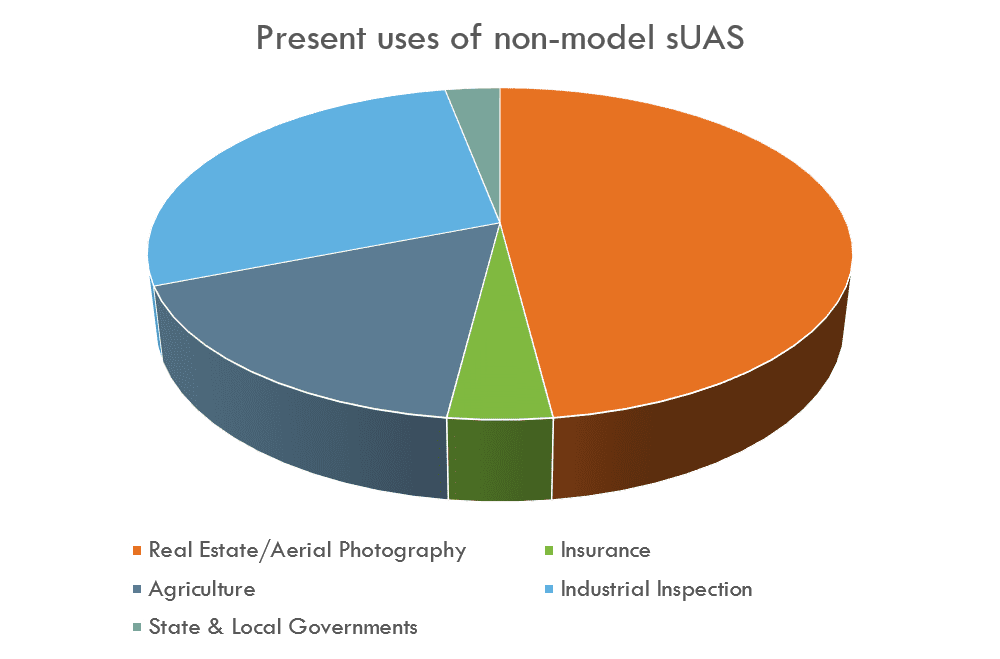

This pie chart from the FAA shows in a general sense how commercial drones are being used in the U.S. By far the most common use is aerial photography and mapping, followed by industrial inspection and agriculture. Insurance and state & local governments round out the chart. Construction is not represented separately on this chart, but it has been identified as the fastest growing industry segment in terms of drone use.

Why Drones?

Why Drones?

Using drones in commercial settings can clearly save time and money in many different ways, including the following:

- Outputs from drone applications can provide support, such as 3D modeling of existing facilities, evidence for insurance or legal claims, or cause-finding efforts for incident investigations.

- Drones can also be used to objectively monitor changes over time, such as erosion control, flood rise and water damage, or the rate of deterioration of fixed outdoor assets like tanks and towers.

- Sensors and software designed for drones offer quick, convenient means to measure stockpile volumes and inventories, evaluate flood plains, or quantify spills.

- Data captured can be used proactively to anticipate environmental risks, indicate preventive maintenance needs, or inform everyday decision-making.

- Drones can quickly and accurately determine stockpile volumes, which is very useful in the mining and aggregate industries.

- Finally, one of the most important uses of drones is to reduce employee exposure to hazardous conditions. These might include working at heights, confined spaces, or any situation where there is a risk of injury or death.

Drone Applications in Action

Let’s take a look at two examples of drones in action.

Application 1: Cause Finding.

Drones are being used across various industries to enhance cause-finding efforts. These tools are especially useful when hazardous materials or conditions are involved, and when the assets involved are on fire, at height, or pose a high safety risk to those involved.

One example of this is railroad derailment prevention. Standard derailment prevention operations involve derailment cause-finding efforts, such as interviewing those involved, walking the site and taking photos by hand and at eye-level. Derailment sites for large Class I railroads can be well over a mile long and can include spilled hazardous materials or active fires depending on the severity of the incident. Inspecting these sites can be time consuming, risky and, since these events are always unplanned, they can be disruptive to those involved.

Using drones, companies have been able to fly a derailment site in a fraction of the time it would have taken a person or persons to walk the entire site. With a LiDAR unit attached to the drone, companies scan the site and, using the data points generated during data collection efforts, recreate the accident scene to scale back at home base. This technology allows for more advanced analytics to be run on the incident. By recreating the accident scene using the data gathered by the drone and an appropriate software package, companies have been able to pinpoint the exact reasons that a train has derailed.

In one such instance, a company was able to determine that one of its trains was loaded in such a way that the push and pull being placed on the couplers was stressed to the point of breakage after the train went over and down a section of undulating territory at a certain speed. The company was able to analyze the degree of the undulation, the relative age of the coupler(s) involved, and the exact moment and location of the derailment. By digitally reconstructing the scene, they could see exactly which part of the train began to wobble, why it became unsteady and what caused the trajectory observed at the derailment site. With the application of UAS technology, the company was able to turn these detailed insights into multiple proactive and response mitigation actions.

Application 2: Industrial Inspection.

Drones are being used at processing and manufacturing plants to identify faults and aid in predicting required maintenance on equipment. In certain applications, specially designed drones are flown into hazardous and confined spaces instead of sending workers in.

One example of the latter is the periodic internal inspection of a large industrial boiler at a mine in Utah. Typically, this is accomplished by installing scaffolding down the middle of the boiler so that a team of technicians can climb down and observe specific features looking for cracking and signs of wear. What is normally a week-long process is now done in half a day with a confined space drone, and literally saves hundreds of thousands of dollars, because production is shut down for hours instead of days.

At another tank farm, UAS operators set waypoints to fly the same route periodically to check for irregularities and deterioration on the tanks, as well as evidence of releases from tanks and piping. This allows for proactive repairs and more efficient maintenance efforts. With a thermal imaging camera attached to the drone, the operator can perform a rough visual level check on the tanks to confirm that individual level sensors on the tanks are performing as expected, so that product inventories are accurate.

Enhancing Operations

There are many ways that drones can be used to enhance operations, regardless of industry. Drones offer a tool to access and assess physical conditions, minimize risks, and enhance employee efficiency during job tasks that are otherwise routine/time consuming, difficult to accomplish (i.e., have a high safety risk, exposure to hazardous materials that could result in injury or death), challenging to reach/excessively large (i.e., working at heights or in confined spaces), or time-sensitive.

When implemented appropriately, using drones often results in a solution that is:

- Faster – Significantly reduce manhours to complete work (e.g., inspections, audits, monitoring) without requiring plant shutdown.

- Safer — Eliminate the need for humans to complete high-risk activities (e.g., climbing towers, entering confined spaces, inspecting disaster zones).

- More accurate — Gather comprehensive and reliable data with less room for human error and less variability.

Learn more about Kestrel’s UAS Program Management services. Be sure to check out the entire Drones 101 series:

Comments: No Comments

The Role of ERP in Food Safety Compliance

Is your organization faced with these challenges?

- Significant industry disruptions with changing consumer demand

- Growing complexity in supply chains

- More stringent food safety mandates

We can help. Through Kestrel’s strategic alliance with Ultra Consultants, our whitepaper—The Role of ERP in Food Safety Compliance–provides in-depth insight to address these challenges.

You’ll learn:

- How to leverage enterprise technology to assist in food safety compliance.

- How to implement the appropriate processes and systems to help manage recalls, reporting, and document control.

- What Enterprise Resource Planning (ERP) system requirements are critical to help today’s food processor.

- Why gaining flexibility to respond to changing regulatory requirements is so important.

Download The Role of ERP in Food Safety Compliance today to get a better understanding of the role ERP systems can play in achieving food safety compliance.

Drones 101: Terminology & Technology

This is the first article in Kestrel’s Drones 101 series.

Industries like transportation, manufacturing, utilities, mining, construction, oil and gas, and agriculture are crucial to our country’s infrastructure, particularly in a rapidly changing global market. Yet these industrial sectors continually face the challenges of an aging workforce and high-risk job tasks, including exposure to moving freight cars, high-voltage transmission lines, and hazmat materials and risks of slips, trips, falls, maiming and premature death.

Emerging Technology

Fortunately, drones are an emerging technology that offers a solution both to the shrinking workforce and as an additional mitigation tactic for various operational safety needs of heavy industries.

What was once a very niche market, drones are emerging into an important new phase: everyday use of drone technology in the workplace. It’s no longer just tech-savvy companies that are using drones. Enterprise-level Unmanned Aerial System (UAS) operations are becoming a big deal in industry. Organizations ranging from municipalities and agriculture companies to the Fortune 500s are getting involved in drone operations.

In another three to five years, it will potentially make business sense for nearly every major industrial company to incorporate UAS technologies into their operations for two reasons:

- Drones are effective at both mitigating risks and increasing operational efficiency.

- Drones are a tool that can bolster workforce recruitment and retention efforts.

Terminology & Technology

As drones become more popular and the industry continues to grow, newer and more varied versions of them are hitting the market, making it difficult to keep up with the technology and the related terminology.

If you’ve observed or read anything about drones, you may have noticed a few acronyms thrown around, and that can be a little confusing. Some of the most common terminology includes the following:

- Drone is used to define just about any type of Unmanned Aerial Vehicle (UAV). The term refers to many different types of an unmanned aircraft of various sizes, which are used for multiple functions, ranging from armed forces aircraft to hobbyists taking amateur digital photography.

- Unmanned Aerial Vehicle (UAV) refers to the platform, airframe, or body of the craft you are flying. The term can be used interchangeably with drone.

- Unmanned Aerial System (UAS) includes the vehicle or aircraft, the controller, and the link(s) that connect them. A small Unmanned Aerial System (sUAS) is a UAS weighing less than 55 pounds at takeoff and landing.

It is best practice to use UAS in formal documents like policies and procedures. If you have a diverse approach that includes both light and heavy drones, then specifying whether a document pertains to sUAS or UAS operations would be optimal, as the regulations vary based on weight, and your operational policies and procedures would need to reflect this.

Types of UAS

While there are variety of drone technologies on the market, the three main types of UAS available in the commercial space are the following:

- Multi-rotor UAS is the most popular drone type for both commercial use and for hobbyists. This type of drone is typically less difficult to operate. They offer vertical take-off and landing and the ability to hover, both of which can result in highly detailed data points and targeted insights. Quad-, hexa-, and octo-copters are all available (i.e., 4, 6 or 8 rotors). There are a number of typical use cases of multi-rotor drones, including industrial inspections, aerial mapping, site planning and monitoring, cause finding, resource management, crop spraying and many more.

- Fixed-wing UAS function more like an airplane than their multi-rotor counterpart. These drones often resemble small airplanes or mechanical stingrays. They consist of two fixed wings on either side of the craft. This design provides for more efficient aerodynamics and longer flight times (~45-60 min per flight). Fixed-wing have high aerial coverage (up to 2,400 acres per flight) but offer less detailed imagery, are typically unable to hover, and are more suited for covering large areas of land, resulting in large data sets with less detail than you would collect using a multi-rotor or a hybrid UAS. These drones require a suitable runway area for takeoff and landings and are usually able to carry heavier payloads than other types of UAS. Typical uses include beyond visual line of sight (BVLOS) operations, photogrammetry and 3D mapping, crop inspections, and other tasks that require significant area coverage.

- Hybrid UAS are gaining popularity, as these platforms offer the benefits of a vertical takeoff and landing and the ability to fly quickly in a forward motion to cover larger areas of land, while still having the ability to hover. Hovering allows for close-up inspections and produces more detailed information than a quick fly by. Hybrids range in their load carrying capability. Hybrids can be used in many of the same ways as fixed wings and multi-rotors but are most excitingly known for their use in delivery services and unmanned air taxi applications.

Payloads

In addition to the drone itself, there are many types of payloads, which is a generic term for the cameras, sensors, or other equipment that can be attached to and carried by drones:

- Specialized cameras are the most often used payloads for drones.

- Various cameras offer the ability to gather higher resolution images with greater detail.

- LiDAR units can be attached to gather data points from any work site, which can then be translated into 3D-modeling efforts to aid in volumetric applications.

- Thermal/infrared cameras provide heat sensing capability.

- Gas detection cameras detect fugitive gas leaks at pipelines and tanks.

- Multispectral and hyperspectral sensors are electromagnetic energy sensors that offer insight into details on resources that would otherwise be invisible to the human eye.

- Environmental sensors (e.g., chemical sensors) can measure chemical compositions and traces of particular chemical substances, including radioactive particles and particulate matter.

Undoubtedly, the types of drones and the payloads will continue to expand as the market and applicability of drones continues to grow.

Learn more about Kestrel’s UAS Program Management services. Stay tuned for the rest of our Drones 101 series, featuring:

Comments: No Comments

Environmental Liability Management

Cost-effective management of environmental liabilities is a challenge for any organization, but it is particularly challenging for those companies with a large portfolio of liabilities at varying stages of maturity. The complexity of liability management is increased even more for those organizations adhering to generally accepted accounting practices (GAAP), which apply additional requirements to the process. Ultimately, the goal of liability management is to create a reliable system that enables the company to minimize risk and quickly drive projects to closure with as little expenditure of internal and external resources as possible.

The manner in which a liability is accounted (and managed) is based largely on the liability itself and the available information. Environmental liabilities are typically managed as either loss contingencies or asset retirement obligations (AROs). A company may also decide to address certain environmental liabilities as operating expenses or capital expenditures. Regardless, companies should employ a cross-functional team (i.e., finance, law, operations, and EHS departments) to establish and document a repeatable and defensible process—consistent with applicable GAAP standards—for how the liability will be managed. Further, companies should develop standard procedures that define how and when costs associated with the liabilities are estimated.

Environmental Loss Contingencies

An environmental loss contingency represents the cost to remediate an environmental liability where:

- It is probable that the liability has occurred, and

- The cost can be reasonably estimated.

The GAAP for loss contingencies is established in Accounting Standards Codification (ASC) 450-20. In very general terms, environmental loss contingencies include environmental investigations and remediation that are not the result of normal operations and that are generally triggered by a regulatory agency action or order.

As stated, the goal of loss contingency management is to create a system to cost-effectively minimize risk and quickly drive projects to closure, while keeping in mind the ultimate outcome of enabling future final use options to return the property to productive and valuable use without rebound liability.

Lifecycle Costs of Remediation

While the most significant cost of a remediation project is typically the expense of the remediation itself, the overall lifecycle cost of a project can be impacted significantly by the following:

- How efficiently a project moves from stage to stage (milestones) and, ultimately, to closure. Many projects get stuck at some point along this path, often significantly increasing the overall project lifecycle cost. Maintaining project velocity through each milestone can keep costs in check.

- The project team’s understanding of critical aspects of the Conceptual Site Model (CSM) before remedies are selected and implemented. Often, projects jump to a remedy—particularly interim remedies—before there is a clear understanding of the CSM (i.e., constituents of concern (COCs), pathway, receptors), resulting in premature or only partial remediation.

- Failure to address all risks associated with a site. This can include physical risks associated with buildings, foundations, and other historical operating structures and equipment.

- The project team’s understanding of the designed project end point. A periodic assessment of the end point of a project is vital to aligning stakeholders and ensuring that all efforts are directed toward the desired outcome. As data and information are collected on a project, it is sometimes necessary to reset the project strategy toward an alternative end point.

- How efficiently and effectively the project team communicates critical project information for decision making. A portfolio-based approach establishes a standard way of communicating project activities, schedule, and budget. This allows for more efficient communication between critical internal stakeholders (e.g., legal, public relations, real estate, and senior management) and with external consultants/advisers.

Portfolio-Based Management Model

There are several key elements to developing an effective portfolio-based management model, including those described in the sections below.

Standard Project Milestones

Controlling a large number of ongoing site remediation projects requires establishing a series of standard project milestones (i.e., project progressions) and associated work subtasks. This standardization establishes a common language and sets the framework for developing common subtasks for project budgeting and scheduling.

A milestone structure for remediation projects would typically include the items listed below. This structure can be adapted to projects where certain impacts to groundwater or soils can move at different velocities through project milestones.

- Project startup: Early project activities that typically include records review, strategy development, regulatory agreement negotiations, etc.

- Preliminary site investigation: Initial data gathering to assess the nature and extent of the impacts; may end with a Remedial Investigation Report (RIR)

- Site characterization and risk assessment: Complete characterization of the site to develop a CSM based on COCs, pathways, and receptors, and to identify physical aspects of the site that must be addressed as part of the project

- Feasibility study: Assessment of alternative remedial options

- Final design: Post-regulatory approved remedy design

- Implementation and OM&M: Remedy implementation and ongoing operation, maintenance, and monitoring

- End point: The targeted point for each project when all work necessary to eliminate the risk has been conducted or the point when no further work will result in additional risk mitigation

Standardized Work Breakdown Structure

For each of the milestones, a common set of subtasks is established to facilitate the development of detailed project workplans and for schedule and cost tracking. These subtasks ensure that workplans consider all the activities required to complete the work and allow for standardization across projects.

Having standardized project milestones and subtasks creates an additional benefit in that they can be used to create a more consistent and documented method for estimating contingent liability under ASC 450-20. By developing lifecycle cost estimating rules for each milestone, a company can ensure that its projects are using a common estimating logic (i.e., known and estimable) for determining the cost of investigation, design, and remedy implementation. A similar process could also be developed to ensure common estimating standards are applied to AROs ASC 410.

Project Control and Change Management

One common flaw in remediation projects is the tendency to enter into interim remedies or to identify a remedy that is not supported by data. This often results in incomplete remedies being implemented or remedies being installed that are not tied to a clear end point.

Developing standard project workplans allows for efficient project control and change management. As work progresses through milestones, data and information emerge to help identify a data-driven set of alternative remedies or a presumptive remedy. The disciplined progression of a project through milestones prevents projects from jumping to a preferred remedy without supporting data.

In addition, periodic review meetings—a key project control—create touch points to:

- Review all aspects of the project’s scope, schedule, and budget

- Test the validity of the end point

- Emphasize the continued forward momentum of the project

Centralized Project Database

Implementing a centralized database, such as Kestrel’s liability and asset management tools, to house all project workplans and other key documents provides another valuable project control. The central project database becomes the real-time repository for project information. Functionality includes the following:

- An internal database for tracking project scope, schedule, and budget for projects in a web-based workplan format

- Exportable workplans for use outside the database

- Password-protected access of the system to allow consultants to see only their projects and company staff to see all projects

- Front-end dashboard to allow senior management to monitor key project activities/status at a glance

- Ability to store key documents for each project

- Customizable project information page that houses project information (e.g., key contacts, project details, COCs, involved media)

- Customized project reports and summaries

- Ad hoc query capability

Periodic Project Reviews

Despite all good intentions, projects (particularly complicated ones) can drift off track or hit dead ends. When these situations occur, Integrated Site Reviews (ISR) can keep projects progressing to the appropriate end point.

A formal ISR can include an external facilitator for larger, more complex projects or be adapted by the project team for smaller projects. An ISR typically follows these steps to validate the project’s direction or to reset a new direction:

- An ISR team is formed consisting of a cross-functional group of stakeholders that could include the consultant, legal, internal environmental manager, real estate, operational staff, and other outside experts. Pulling together all stakeholders ensures that there is alignment and agreement on the selected end point.

- The ISR team meets (typically for no longer than a day) and goes through a structured review of technical, regulatory, legal, and third-party project drivers.

- Depending on the stage of the project, a blue sky set of alternative end points is identified.

- The alternative end points are developed, discussed, and evaluated.

- In the end, the current end point is either validated or a new end point is developed.

- All necessary changes to the project workplan are made.

Companies can respond to the challenge of managing contaminated properties by either internally staffing up to provide day-to-day oversight of the projects or by outsourcing the projects to a consultant, who can efficiently execute the project and serve as the public face. Whichever route a company decides to take, following the key elements described above will allow for effective portfolio-based management that will reach the desired end points.

Comments: No Comments

Risk-Based Standards Workshop: March 27

Don’t miss this free workshop hosted by DNV GL in Chicago on Wednesday, March 27, 2019.

Risk-Based Standards Workshop – How Emerging ISO Requirements Are Impacting Business

Environmental, Product Compliance, Health & Safety, Supply Chain & Food Safety

Join DNV GL Business Assurance North America Regional & Technical Management, Global Accreditation Management, as well as DNV GL Digital Solutions and key industry experts for this day-long workshop. Presenters will provide lessons learned about the following standards and topics: ISO 14001, ISO 45001, Product Compliance, and Supply Chain.

The second half of the day will feature a workshop on Food Safety. Kestrel Principal Roberto Bellavia will be talking about mitigating allergen risks. Other topics include supply chain management, food safety culture, and food fraud.

Comments: No Comments

March 7 Webinar: Food Safety Compliance & ERP

Showcase Webinar – Food Safety Compliance and ERP:

How to Stay on the Safe Side

Thursday March 7, 2019 1 p.m. CT

Food and beverage processors face significant disruptions with changing consumer demand, growing complexity in supply chains, and ever stringent food safety mandates.

Today’s food and beverage processor must implement the appropriate processes and systems that not only manage recalls, reporting and document control, but also offer the flexibility to respond to changing regulatory requirements.

Kestrel and Ultra Consultants are partnering to offer you an educational webinar session taking place March 7, 2019 to learn what it takes to integrate compliance programs into core business processes and systems.

The session details how to meet a pressing need – selecting and implementing the right technology to meet strict food safety mandates.

Key Takeaways:

- Understand the key food safety trends and regulations impacting the sector.

- Get an overview of strategies to help meet and sustain food safety compliance, certifications and regulatory mandates.

- See the must-have ERP features to help reduce operational risks, achieve food safety requirements, and realize sustained value through effective use of enterprise technology.

Who Should Attend?

- C-level leaders at food and beverage processing companies

- Quality, Compliance, Finance leadership

- ERP, IT Directors

- Operations Directors, Production leadership

- Anyone responsible for overall business process improvement

Comments: No Comments

Upcoming Coffee & FSVP Workshops: March 2019

Kestrel Management is teaming with Firedancer Coffee Consultants

to bring you two unique training opportunities this March in Rolling Meadows, Illinois.

Space is limited, so don’t miss your chance to register now!

Specialty Coffee Association’s Coffee Skills Program: Green Coffee Foundations: March 20, 2019

Specialty Coffee Association’s Coffee Skills Program: Green Coffee Foundations: March 20, 2019

Join Firedancer Coffee Consultants for the SCA Coffee Skills Program’s one-day Green Coffee Foundations course. This introductory course covers key concepts surrounding green coffee, from growing the plant through processing, shipping, and storage, to arrival at a roastery. This course has been adapted to focus on known hazards in the supply chain of coffee, where they occur, and/or how they can be controlled or eliminated to help set the stage for the two-day FSVP course.

This is a certificate program from the Specialty Coffee Association, with a written and practical test at the end of the day. Cost of the course is $400. Use Code KM2019-25 when registering for a 25% discount on tuition fees. REGISTER NOW!

Foreign Supplier Verification Program (FSVP) Workshop: March 21-22, 2019

Foreign Supplier Verification Program (FSVP) Workshop: March 21-22, 2019

The FDA is starting to inspect importers as of September 2018. It’s time to be prepared. This two-day course is focused on building plans for green coffee producers, exporters and importers, but will cover the full extent of the law. Kestrel will lead attendees through the requirements for building a FSVP. The last half day will be spent building a model plan as a group. A prerequisite class is not required for the FSVP course, but having a strong understanding of FSMA, Good Manufacturing Practices, Hazard Analysis, and Preventive Controls would be beneficial.

Cost of the course is $895 per person, which includes a workbook, templates, lunch both days, and a certificate in FSVP. REGISTER NOW!

Comments: No Comments

OSHA Final Rule: Electronic Recordkeeping

On January 24, 2019, OSHA published the final rule revising the Improve Tracking of Workplace Injuries and Illnesses regulation. This rule rescinds the requirements for establishments with 250 or more employees to electronically file information from OSHA Forms 300 and 301. These establishments will continue to submit information from their Form 300A. In short, all covered employers must electronically submit, as follows:

- Establishments with 250 or more employees that are subject to OSHA’s recordkeeping regulation must electronically submit to OSHA some of the information from the Log of Work-Related Injuries and Illnesses (OSHA Form 300), the Summary of Work-Related Injuries and Illnesses (OSHA Form 300A), and the Injury and Illness Incident Report (OSHA Form 301).

- Establishments with 20-249 employees in certain high-risk industries must electronically submit to OSHA some of the information from the Summary of Work-Related Injuries and Illnesses (OSHA Form 300A).

- Establishments with fewer than 20 employees at all times during the year do not have to routinely submit information electronically to OSHA.

In the final rule, OSHA emphasized the new rule does not change any employer’s obligation to complete and retain injury and illness records under OSHA’s regulations for recording and reporting occupational injuries and illnesses.

Additionally, OSHA is amending the regulation to require employers to submit their Employer Identification Number (EIN) electronically as part of their submission to enhance data and further improve worker safety and health.

Post Your OSHA 300A by February 1

Do not forget! The OSHA Form 300A log must be posted every year by February 1, summarizing all injuries from the previous year. The log must be visible from February 1 until April 30, and must be signed by a company executive or authorized representative, indicating that the information is true and accurate.

Comments: No Comments

How to Effectively Resource Compliance Obligations

Regulatory enforcement, customer and supply chain audits, and internal risk management initiatives are all driving requirements for managing regulatory compliance obligations. Many companies—especially those that are not large enough for a dedicated team of full-time staff—struggle with how to effectively resource their regulatory compliance needs.

Striking a Balance

Using a combination of in-house and outsourced resources can provide the appropriate balance to manage regulatory obligations and maintain compliance.

Outsourcing provides an entire team of resources with a breadth of knowledge/experience and the capacity to complete specific projects, as needed. At the same time, engaging in-house resources allows the organization to optimize staff duties and ensure that critical know-how is being developed internally to sustain compliance into the future.

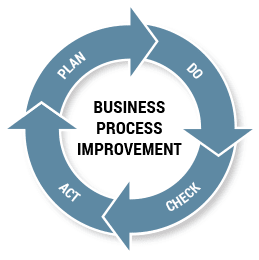

Programmatic Approach to Compliance Management

Taking a balanced and programmatic approach that relies on internal and external resources and follows the three phases outlined below allows small to mid-size companies to create standardized compliance management solutions and more efficiently:

- Identify issues and gaps in regulatory compliance

- Achieve compliance with current obligations

- Realize improvements to compliance management

- Gain the ability to review and continually improve compliance performance

Phase 1: Compliance Assessment

A compliance assessment provides the baseline to improve compliance management and performance in accordance with current business operations and future plans. The assessment should answer the following questions:

- How complete and robust is the existing compliance management program in comparison with standard industry practice?

- Does it have the capability to yield consistent and reliable regulatory compliance assurance?

- What improvements are needed to consistently and reliably achieve compliance and company objectives?

It is important to understand how complete, well-documented, understood, and implemented the current processes and procedures are. Culture, model, processes, and capacity should all be assessed to determine the company’s overall compliance process maturity.

Phase 2: Compliance and Program Improvements

The initial analysis of the assessment forms the basis for developing recommendations and priorities for an action plan to strengthen programs, building on what already exists. The goal of Phase 2 is to begin closing the compliance gaps identified in Phase 1 by implementing corrective actions, including programs, permits, reports, training, etc.

Phase 2 answers the following questions:

- What needs to be done to address gaps and attain compliance?

- What improvements are required to existing programs?

- What resources are required to sustain compliance?

Phase 3: Ongoing Program Management

The goal of Phase 3 is to improve program processes to eliminate compliance gaps and transition the company from outsourced compliance into compliance process improvement/program development and implementation. This is done by managing the eight functions of compliance—identifying what’s needed, who does it, and when it is due. Ongoing maintenance support may include periodic audits, training, management review assistance, Information Systems (IS) support, and other ongoing compliance activities.

Case Study

For one Kestrel client, business growth has increased at a rate prompting proactive management of the company’s regulatory and compliance obligations. Following a Right-Sized Compliance approach, Kestrel assessed the company’s current compliance status and programs/processes/procedures against regulatory requirements. This initial assessment provided the critical information needed for the Kestrel team to help guide the company’s ongoing compliance improvements.

Coming out of the onsite assessment, Kestrel identified opportunities for improvement. Using industry standard program templates, in combination with operation-specific customization, Kestrel created programs to meet the identified improvement from the assessment. Kestrel then provided onsite training sessions and is working with the company to develop a prioritized action plan for ongoing compliance management.

Using the appropriate methods, processes, and technology tools, Kestrel’s programmatic approach is allowing this company to implement EHS programs that are designed to sustain ongoing compliance, achieve continual improvements, and manage compliance with efficiency through this time of accelerated growth.

Making the Connection

Kestrel’s experience suggests that the connection between management and compliance needs to be well synchronized, with reliable and effective regulatory compliance commonly being an outcome of consistent and reliable program implementation. This connection is especially important to avoid recurring compliance issues.

Following a programmatic approach allows companies to realize improvements to their compliance management and:

- Organize requirements into documented programs that outline procedures, roles/responsibilities, training requirements, etc.

- Support management efforts with technology tools that create efficiencies and improved data management

- Conduct the ongoing monitoring and management that are vital to remain in compliance

- Gain the inherent capacity, capability, and maturity to comply, review, and continually improve compliance performance

Comments: No Comments

Compliance Assurance Review

An audit provides a snapshot in time of a company’s compliance status. An essential component of any compliance program—health and safety, environmental, food safety—an audit captures compliance status and provides the opportunity to identify and correct potential business losses. But what about sustaining ongoing compliance beyond that one point in time? How does a company know if it has the processes in place to ensure ongoing compliance?

Creating a Path to Compliance Assurance

A compliance assurance review looks beyond the “point-in-time” compliance to critically evaluate how the company manages compliance programs, processes, and activities, with compliance assurance as the ultimate goal. It can also be used as a process improvement tool, while ensuring compliance with all requirements applicable to the company.

This type of review is ideal for companies that already have a management system in place or strive to approach compliance with health and safety, environmental, or food safety requirements under a management system framework.

Setting the Scope

The scope of the review is tailored to a company’s needs. It can be approached by:

- Compliance program/topic where the company has had routine compliance failures

- Compliance program/topic that presents a high risk to the company

- Compliance program/topic that spans across multiple facilities that report to a central function

- Location/product line/project where the company is looking to streamline a process while still ensuring compliance with multiple legal and other requirements

While each program, project, or location may differ in breadth of regulatory requirements, enforcement priorities, size, complexity, operational control responsibilities, etc., all compliance assurance reviews progress through a standard process that ties back to the management system.

Continual Compliance Improvements

Through a compliance assurance review, the company will define and understand:

- Compliance requirements and where regulated activities occur throughout the organization

- Current company programs and processes used to manage those activities and the associated level of program/process maturity

- Deficiencies in compliance program management and opportunities for improvement

- How to feed review recommendations back into elements of the management system to create a roadmap for sustaining and continually improving compliance