Comments: No Comments

EPA Regulatory Alert: Ban on TCE

Trichloroethylene (TCE) is an extremely toxic chemical used in cleaning and furniture care products, degreasers, brake cleaners, and tire repair sealants, amongst other uses. TCE is commonly found at Superfund sites as a contaminant in soil and groundwater. It is known to cause liver cancer, kidney cancer, and non-Hodgkin’s lymphoma, as well as damage to the central nervous system, immune system, reproductive organs, and fetal health. Environmental and human health risks are present with even very small concentrations of TCE.

Proposed Rule

On October 23, 2023, EPA issued a proposed rule under the Toxic Substances Control Act (TSCA) to ban the manufacture, processing, distribution, and use of TCE to prevent soil and groundwater contamination and protect the public from the associated health risks. This proposal aligns with President Biden’s Cancer Moonshot approach to end cancer and advances the Administration’s commitment to environmental justice.

EPA’s proposed TCE ban would phase out the manufacturing, processing, distribution, and use of TCE over the course of one year. For uses where a longer transition timeframe is necessary (e.g., critical Federal Agency uses, battery separators, manufacture of certain refrigerants), EPA is proposing stringent worker protections to reduce exposure while phasing out TCE.

How This Impacts You/What You Need to Do

It is important for facilities to have a good understanding of chemicals used onsite and to start taking action now to phase out any TCE, as the one-year phaseout period will be quick. Facilities should:

- Inventory Chemicals: Take an inventory of onsite chemicals to determine whether the facility manufactures, distributes, and/or uses any TCE. Consult safety data sheets (SDS) for ingredients. TCE can be referred to as trichlor, trike, or tri and may be sold under a variety of trade names. TCE is identified by its Chemical Abstract Service (CAS) Number: 79-01-6.

- Identify Alternatives: For most uses of TCE as a solvent, safer alternatives are already available. EPA’s Safer Choice Program provides a list of solvents (including degreasers) identified as “safer” alternatives. The University of Massachusetts Toxics Use Reduction Institute (TURI) also has an extensive database of safer alternatives to TCE (and other toxic solvents and cleaners) used for degreasing purposes.

- Make the Transition: The best way to prevent TCE from entering the environment is to eliminate its use in facility operations (i.e., source reduction). Follow EPA’s Pollution Prevention (P2) approach to implement cleaning and degreasing modifications, such as switching to aqueous and less toxic cleaning solvents, adopting other mechanical cleaning techniques, or substituting equipment.

- Dispose Correctly: TCE waste can be characterized in a few ways depending on what it is and how it is used (or not used). TCE waste should be properly characterized and managed at a permitted disposal facility—most likely an incinerator.

Comments: No Comments

EPA Regulatory Alert: TSCA Risk Evaluation Process

The Environmental Protection Agency’s (EPA) Toxic Substances Control Act (TSCA) (modified in 2016 by the Frank R. Lautenberg Chemical Safety Act) requires EPA to conduct a risk evaluation to determine whether a chemical substance presents an unreasonable risk to health or the environment under the conditions of use.

On October 19, 2023, EPA proposed a new rule to strengthen its process for conducting these risk evaluations under TSCA. The rule is intended to:

- Ensure EPA’s processes better align with the provisions of the law.

- Support more robust evaluations that account for all risks.

- Provide a foundation for protecting workers and communities from toxic chemicals with more protective rules for workers and communities.

TSCA Background

The TSCA inventory is a list of all existing chemical substances manufactured, processed, or imported in the U.S. The current inventory contains 86,718 chemicals, of which 42,242 are active in U.S. commerce. EPA evaluates existing and new chemicals for the inventory:

- Existing chemicals: EPA prioritizes existing chemicals on the list and selects chemicals to determine if the risk is reasonable or unreasonable. If the risk is unreasonable, EPA will impose restrictions to eliminate the risk. The list of ongoing and completed evaluations is available online.

- New chemicals: Any chemical that is not currently on the inventory is considered a “new chemical substance.” Anyone who plans to manufacture or import a new chemical substance for a non-exempt commercial purpose must provide EPA with a Premanufacture Notice (PMN) at least 90 days before initiating the activity. During the notice review period, EPA will review the PMN and determine if the chemical presents unreasonable risk(s) to human health or the environment.

Proposed Provisions

The new proposed rule aims to strengthen EPA’s process for conducting its TSCA chemical risk evaluations. EPA initially finalized a risk evaluation framework rule in 2017; however, it was quickly challenged in Court. The October 2023 proposed rule addresses the Court’s revisions and adds provisions requiring that risk evaluations:

- Consider the disproportionate harms facing overburdened communities, including multiple exposure pathways to the same chemical and combined risks from multiple chemicals.

- Be comprehensive and not exclude conditions of use or exposure pathways.

- Consider risks to workers.

- Use best available science.

- Provide a single determination of whether the chemical presents unreasonable risk, rather than multiple determinations based on individual chemical uses.

- Ensure transparency through updated risk evaluation documents.

- Better align manufacturer-requested risk evaluations with EPA-initiated risk evaluations.

While many of these changes were announced in 2021 and have been incorporated into TSCA risk evaluations over the past two years, they have not been finalized in the Code of Federal Regulations. Doing so will help ensure more certainty regarding the process for conducting TSCA risk evaluations moving forward.

How This Impacts You/What You Need to Do

This rulemaking aligns with Goal 7 of the FY 2022-2026 EPA Strategic Plan to ensure the safety of chemicals for people and the environment. That Plan focuses on strengthening EPA’s ability to successfully implement TSCA with appropriate resources to complete EPA-initiated chemical risk evaluations and risk management actions.

- If you manufacture or import chemicals, determine if the chemical is on the TSCA inventory.

- If you manufacture or import a chemical that is not on the inventory, complete a PMN at least 90 days before initiating the activity.

EPA will conduct a risk evaluation to determine the risk(s) the chemical poses to human health or the environment. Under the proposed rule, these evaluations will be more robust to account for all risks to better protect workers and communities from toxic chemicals.

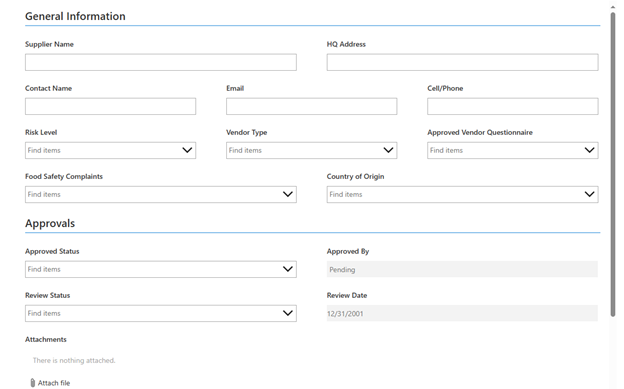

Tech Corner: Vendor Management

Functionality: What does it do?

Vendor management is the process of coordinating vendors and suppliers. It includes activities such as selecting and approving suppliers, reviewing qualifications, negotiating contracts, ensuring quality, and compiling required documentation. KTL’s vendor management/supplier approval system provides a web-based tool to effectively approve and manage vendors and suppliers. It enables businesses to control costs, minimize potential risks related to vendors/suppliers, and meet regulatory requirements (e.g., Food Safety Modernization Action (FSMA) Foreign Supplier Verification Program (FSVP) Rule).

Benefits: Why do you need it?

KTL’s web-based supplier approval system:

- Provides a checklist to ensure all vendors and suppliers meet required criteria (e.g., certifications, licenses, performance history).

- Manages vendor and supplier-specific requirements.

- Stores and organizes supplier documents and records; suppliers can upload their own documents in a secure folder (if external user access is allowed).

- Enables facilities to conduct and manage vendor evaluations.

- Sends email notifications of supplier-related compliance deadlines.

Technology Used

- SharePoint

- Power Automate (for email notifications)

Comments: No Comments

Food Allergen Programs: Updated FDA Draft Guidance

According to the Food and Drug Administration (FDA), millions of Americans have food allergies. While most reactions are mild, some people experience severe or even life-threatening symptoms. FDA’s Current Good Manufacturing Practice (cGMP), Hazard Analysis, and Risk-Based Preventive Controls for Human Food (PCHF) Rule (21 CFR Part 117) requires domestic and foreign food facilities that manufacture human food develop and implement a Food Safety Plan that includes an Allergen Program to address this concern.

Eight Becomes Nine

While many different foods can cause many different types of reactions and symptoms, the Food Allergen Labeling and Consumer Protection Act of 2004 (FALCPA) identified what has commonly been known as the “Big 8” major allergens:

- Milk

- Eggs

- Fish (e.g., bass, flounder, or cod)

- Crustacean shellfish (e.g., crab, lobster, or shrimp)

- Tree nuts (e.g., almonds, pecans, or walnuts)

- Wheat

- Peanuts

- Soybeans

Sesame was added as the ninth major food allergen when the Food Allergy Safety, Treatment, Education, and Research (FASTER) Act became effective on January 1, 2023. FALCPA requires that food labels clearly identify the food source names of any ingredients that are a major food allergen or contain protein derived from a major food allergen. The intent of FALCPA is to help allergic consumers identify foods or ingredients that they should avoid to prevent an allergic or other reaction due to hypersensitivities.

New Guidance

On the heels of the FASTER Act’s effective date, FDA recently published draft guidance for Food Allergen Programs in September 2023. This is part of the Agency’s ongoing updates to its Draft Hazard Analysis and Risk-Based Preventive Controls for Human Foods Guidance for Industry. Comprised of 16 chapters, FDA has been releasing new chapters since the guidance was announced in 2016 as they are developed to help facilities develop a Food Safety Plan in accordance with regulatory requirements. The most recent guidance published includes Chapter 11: Food Allergen Program.

Chapter 11 focuses on developing a Food Allergen Program to ensure finished food is properly labeled for major food allergens and, even more so, to protect food from major food allergen cross-contamination. According to FDA, “Some manufacturers are intentionally adding sesame to products that previously did not contain sesame and are labeling the products to indicate presence, rather than taking appropriate measures to minimize or prevent cross-contact.” Through the new guidance, FDA is encouraging industry to prevent allergen cross-contamination rather than intentionally adding sesame (or other major allergens) to products and then labeling them to comply with the law.

FDA recognizes the challenges of ensuring products are allergen-free, and the guidance is intended to help companies find solutions to meet the needs of consumers with food allergies. Chapter 11 explains how to develop and implement a Food Allergen Program by providing detailed recommendations for each aspect of the Program. It offers multiple examples for illustrative purposes that demonstrate ways to significantly minimize allergen cross-contact and undeclared allergens using cGMPs and preventive controls.

Labeling errors are the major reason for most FDA food allergen recalls. As such, the new chapter also offers guidance on how to monitor and verify that food allergies are properly declared and correctly labeled. In addition, the guidance addresses what facilities can do when allergen presence due to cross-contact cannot be completely avoided, including using allergen advisory statements.

Previously Published Guidance

The comprehensive Draft Guidance for Industry remains a work in progress. In addition to Chapter 11: Food Allergen Programs, the following draft chapters are currently available:

- Chapter 1: The Food Safety Plan

- Chapter 2: Conducting a Hazard Analysis

- Chapter 3: Potential Hazards Associated with the Manufacturing, Processing, Packing, and Holding of Human Food

- Chapter 4: Preventive Controls

- Chapter 5: Application of Preventive Controls and Preventive Control Management Components

- Chapter 6: Use of Heat Treatments as a Process Control

- Chapter 14: Recall Plan

- Chapter 15: Supply-Chain Program for Human Food Products

- Chapter 16: Acidified Foods

FDA plans to still publish the following chapters as they are developed:

- Chapter 7: Use of Time/Temperature as a Process Control

- Chapter 8: Use of Product Formulation or Drying/Dehydrating as a Process Control for Biological Hazards

- Chapter 9: Validation of a Process Control for a Bacterial Pathogen

- Chapter 10: Sanitation Controls

- Chapter 12: Preventive Controls for Chemical Hazards

- Chapter 13: Preventive Controls for Physical Hazards

- Chapter 17: Classification of Food as Ready to Eat or Not Ready to Eat

Whether for allergen management or other identified hazards, taking a systematic approach to establishing risk-based preventive controls helps protect food products—and the consumer—from biological, chemical, and physical risks. FDA’s guidance can provide an excellent resource for meeting regulatory requirements and protecting consumers.

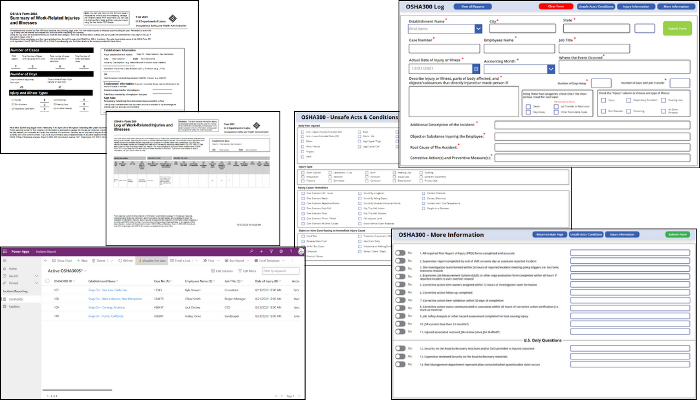

Tech Corner: OSHA 300 Log Management

Functionality: What does it do?

The Occupational Safety and Health (OSH) Act requires certain employers to prepare and maintain records of work-related injuries and illnesses. Employers must keep an OSHA 300 Log and OSHA 300A Summary for each establishment or site that documents specific details when an incident occurs. KTL’s OSHA 300 PowerApp is a comprehensive intake form tailored to OSHA 300 and OSHA 300A requirements that makes it easier to collect, search, and analyze data—and maintain OSHA compliance.

Benefits: Why do you need it?

KTL’s OSHA 300 PowerApp provides the following:

- Easier data entry. The app guides users through all required OSHA questions to help ensure no crucial data points are missed.

- Reduced errors. The intuitive design and in-built checks reduce the chances of errors, leading to more accurate reporting.

- Improved searchability. Microsoft Dataverse provides quick and efficient access to stored records. The digital format makes it easy to filter, search, and analyze records and data to offer deeper insights into safety performance.

- Mobility. The PowerApp can be accessed from any device, anytime, anywhere, making the reporting process more flexible.

- Data security. Log entries are stored safely, ensuring data integrity and security.

- Improved visualization. Incident data can be viewed in real-time as two paginated reports:

- OSHA 300 Log: Detailed record of work-related injuries and illnesses.

- OSHA 300A: Summary of the OSHA 300 Log, which can be displayed prominently at workplaces.

Technology Used

- PowerApps

- Microsoft Dataverse

- Power BI

Comments: No Comments

Environmental Non-Conformances: Knowledge Is Power

Audits offer a systematic, objective tool to assess compliance across the workplace and to identify any opportunities for improvement. Audits can also present an opportunity for organizational learning and development, particularly related to non-conformances. In many cases, non-conformances are not a result of intentionally ignoring the requirements; rather, they can often be attributed to not fully understanding compliance requirements.

KTL has identified three areas where our environmental auditors repeatedly identify non-conformances that stem from lack of knowledge or understanding—and what companies need to know to eliminate them.

Waste Handling

Do you know your generator status? If a facility does not accurately determine its generator status, it will likely have waste handling non-conformances during an audit.

Generator status is determined by the volume of hazardous waste the facility generates per month and accumulates onsite. There are three categories of generators:

- Very Small Quantity Generator (VSQG)

- Small Quantity Generator (SQGs)

- Large Quantity Generator (LQG)

Determining which category a facility falls into is key to understanding which requirements apply and, subsequently, maintaining compliance. How much waste does the facility generate? How much waste does the facility accumulate? What types of risks does this waste present? This information will dictate whether the facility is a VSQG, SQG, or LQG.

Hazardous waste generator status should be registered with the Environmental Protection Agency (EPA) and/or state environmental agency. Generator status can be verified in the EPA’s Enforcement and Compliance History Online (ECHO) database. If the information is incorrect, the facility will need to complete Form 8700-12 to ensure generator status is correct, as VSQGs, SQGs, and LQGs have some different requirements due to their potential impacts on the environment. From there, the facility should identify the applicable regulatory requirements and train staff on their responsibilities to avoid non-conformances.

Chemical Spillage

Any facility that generates waste needs to determine what waste is hazardous. In the event of a spill, it is critical that the facility can characterize whether the spill cleanup is hazardous or nonhazardous, as that will dictate the appropriate response. If a waste determination/characterization has been completed, this can typically be determined from the chemical’s Safety Data Sheet (SDS).

Emergency preparedness is another element of compliance when it comes to a spill. Facilities need to make sure supplies are appropriate for any spill that could potentially occur. For example, if a forklift battery leaks, that is an acid spill. The facility spill kit should contain baking soda to neutralize the acid.

Universal Waste

EPA regulates a class of waste referred to as universal waste. Universal wastes are hazardous in their composition but can be recycled. Under EPA’s definition, the following are the current universal waste streams:

- Batteries (Li, Ni-Cd, Ag, Hg)

- Mercury-containing equipment (MCE)

- Electric lamps

- Cathode ray tubes (in electronics)

- Pesticides (recalled or farmer-generated)

- Non-empty aerosol cans (in some states)

- Others, as determined by state-specific regulations

EPA regulators have focused on these waste streams as a source of penalty for the past decade. Failure to collect, label, store, and recycle universal waste properly is one of the most frequent citations issued. Although not as complex as the requirements for proper hazardous waste management, universal waste has nuances that a generator must be aware of to properly meet the regulatory requirements.

Universal waste doesn’t “count” against generator status. It does not have to be manifested but generally requires specific labeling language (e.g., universal waste lamp, universal waste battery). Universal waste must also be stored in closed, intact containers. Universal waste can only be kept onsite for one year, so these containers should be dated when the first waste is added as a best practice or a log/schedule should be maintained of dates. A mail-back program for universal waste may be an appropriate consideration for generators of small quantities of universal waste to comply with disposal regulations.

Remedy for Compliance

Many of the non-conformances found in these three areas can be relatively simply remedied—or avoided altogether by making sure facilities educate and train impacted staff on how to:

- Inventory, characterize, and quantify wastes.

- Determine/verify generator status.

- Identify applicable federal and state regulatory requirements based on the above. States may have additional rules provided they are at least as stringent as the federal requirements.

- Implement the appropriate procedures, programs, systems, and training to eliminate non-conformances.

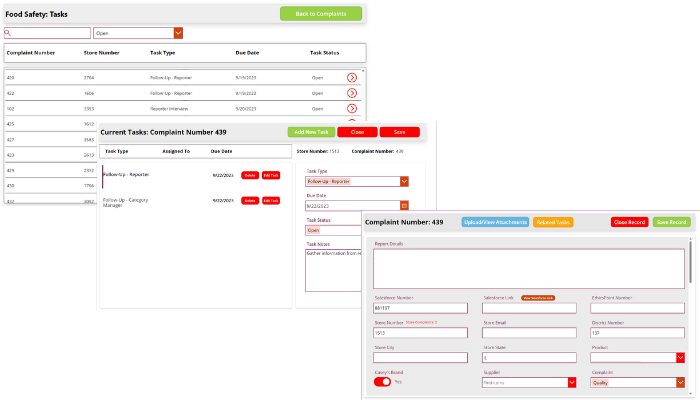

Tech Corner: Customer Complaints Log

Functionality: What does it do?

Whether a company sells directly to consumers or to other manufacturers, managing, monitoring, responding to, and trending customer complaints is an important part of a risk management strategy. KTL’s customer complaints log provides a central location for companies to capture and respond to customer complaints—and then trend that data to ensure complaints are tracked to closure and any necessary changes are made to alleviate company risk.

Benefits: Why do you need it?

A web-based customer complaints log:

- Simplifies collection of customer complaint information via electronic forms.

- Aggregates all customer complaints in one central database to support the management and trending of customer complaint data.

- Documents, assigns, and tracks resolution of customer complaints.

- Establishes follow-up action requirements and associated deadlines to ensure any required changes are made.

- Helps manage the risks associated with customer complaints and potential recalls.

- Meets certification standard requirements for complaint management (e.g., Global Food Safety Initiative (GFSI)).

Technology Used

- Power Apps: Creates customized forms and applications for data capture and initial complaint logging.

- Power BI: Allows for advanced analytics, data visualization, and trending of customer complaint data.

- Power Automate: Automates the workflow, task assignments, reminders, and follow-up actions related to complaints.

Comments: No Comments

Food Safety Certification: Top Non-Conformances

In July, the Safe Quality Food (SQF) Institute published an article citing the most common non-conformances encountered during certification audits. Interestingly, the transition to SQF edition 9 has changed the number and types (i.e., critical, major, minor) of non-conformances SQF is seeing, with non-conformances related to pest prevention, Food Safety Plan, cleaning and sanitation, and management review and internal audits topping the list.

KTL’s food safety experts break down SQF’s top non-conformances and what you can do to address them.

Prioritizing Pest Prevention

According to SQF, pest prevention is the leading non-conformance under edition 9, with both critical and major findings. Exposure to pests—and the diseases they carry—creates the risk of food contamination and the spread of infectious diseases. Companies need a pest prevention program, whether managed internally or by a third-party contractor, that integrates sufficient measures to minimize pest populations. This may include mechanical preventions and controls, waste minimization, or controlled use of pesticides.

KTL Recommendations:

- Review any findings with your food safety team and the pest control contractor, if used. Include frequent review of the approved chemicals or chemicals used for any treatment and ensure the site has access to copies of their safety data sheets (SDSs). Corrective and preventive actions (CAPAs) should be applied to act right away on any open observations. CAPAs should be regularly monitored and tracked to closure. If a third-party contractor is used, open observations should be discussed with the contractor; they may have helpful information on how to handle a pest issue.

- Review pest control trending data at monthly management review meetings. This will help ensure pest prevention data is tracked and monitored. It can also help identify larger, more systemic issues that might necessitate additional CAPAs to resolve the problems.

- Incorporate evaluation of pest prevention performance into the validation and verification schedule.

- Validation should include review of inspection records (at each visit), an annual assessment by the food safety team or pest control provider, and review of trends at the annual management review meeting.

- Verification should include a monthly visual inspection during internal good management practices (GMP) inspections. A simple check to ensure these inspections are thorough enough can involve putting a business card in a tin can for pest control to find and identify on the report.

SQF Tip Sheet: Pest Prevention

Strengthening the Food Safety Plan

The Hazard Analysis and Critical Control Points (HACCP) Food Safety Plan is the foundation of the SQF System. Given this, it makes sense that non-conformances related to the Food Safety Plan always top the list. SQF indicates that many of these findings are now being marked as critical with edition 9. The most common non-conformances include missing hazard analysis, incomplete ingredient hazard analysis, and misidentification of critical control points (CCPs).

KTL Recommendations:

- Review and update the HACCP Plan at least annually or whenever there is a change to operations (e.g., ingredients, processes, equipment, etc.) to ensure all inputs and outputs are identified and appropriately managed.

- Use a risk ranking chart to identify risks; determine their severity and likelihood; and document when a hazard is controlled by a GMP, CCP, or other preventive control (PC).

- Use specification sheets and known information about ingredients to facilitate the identification of hazards during the hazard analysis. Ensure copies of any studies or guidance documents are available to the HACCP team and any applicable updated scientific consensus is reviewed. Hazards should be specifically identified rather than just listed as general categories (e.g., biological, chemical, etc.).

- Document everything in a food safety management system (FSMS). Recordkeeping proves that all requirements of the Plan are met.

SQF Tip Sheet: HACCP Food Safety Plan

Emphasizing Cleaning and Sanitation

Cleaning and sanitation methods vary based on the nature of operations, as well as the microbiological and allergen risks. Regardless, every facility needs to develop, implement, and document a cleaning and sanitation program that fits their production processes. According to SQF, this area remains second on the list of major findings in edition 9.

KTL Recommendations:

- Understand all the areas and equipment that need to be cleaned and sanitized in the facility. Pay attention to the condition of floors, ceilings, walls, doors, etc. to ensure you are maintaining a hygienic and safe environment.

- Create a robust cleaning and sanitation, preventive maintenance, and maintenance schedule. Regular maintenance of equipment, utensils, and building materials is crucial to prevent non-conformances.

- Incorporate monitoring of the cleaning and sanitation program into the validation and verification process:

- Validation: Review sanitation records and logs, environmental monitoring records, and trending data to identify areas of concern.

- Verification: Conduct visual inspections and records review. Consider swab testing to monitor compliance and trends, especially if using a contracted company for cleaning and sanitation. Review GMP inspection findings and CAPAs at monthly management meetings and track to closure.

SQF Tip Sheet: Cleaning and Sanitation

Management Review and Internal Audits

SQF includes management review (2.1.2.1) as minor nonconformance, highlighting the importance of incorporating food safety culture into the review process. Internal audits remain a crucial way to identify areas of improvement, though they are now on the minor non-conformance list.

KTL Recommendations:

- Set objectives/goals for the year and monitor the performance of these objectives at monthly and annual management review meeting. Resources should be allocated appropriately based on trends identified in these meetings to reach goals and ensure the overall effectiveness of the food safety culture.

- Conduct regular GMP inspections, trend results, review them during management meetings, and identify CAPAs, as necessary.

- Distribute food safety questionnaires to personnel to gather input. Review results during management review meetings and use the data collected to create action plans for maintaining or improving scores.

- Conduct a comprehensive internal audit at least annually and address any identified gaps in compliance. Internal audit findings should be reviewed at monthly and annual management review meetings. CAPAs should be assigned for findings, and data can be used to refine food safety objectives/goals.

SQF Tip Sheets: Management Commitment / Internal Audit Plan

Knowing and truly understanding the requirements of the SQF Code—or any of the Global Food Safety Initiative (GFSI) certification standards—is essential to avoiding non-conformances. Paying particular attention to the identified top non-conformances can help facilities to proactively mitigate these risks, strengthen food safety culture, and improve overall compliance.

Comments: No Comments

KTL Welcomes New Environmental Engineer

Tech Corner: Training Tracking

Functionality: What does it do?

Training is a key component of maintaining ongoing compliance—whether with regulatory requirements, supply chain mandates, or internal policies. Having a system that records employee training is critical, especially to ensure policies, procedures, and work instructions are followed. KTL’s training tracking systems allow for the centralized implementation, management, tracking, scheduling, assignment, and analysis of organizational training efforts.

Benefits: Why do you need it?

A web-based training tracking system can help:

- Outline and document training requirements.

- Create training plans and workflows for scheduling training and assignments by job title and function.

- Ensure competency through online quizzes.

- Log and track training and certifications completed—including classes, required reading, online education, CEUs, and outside certifications.

- Track certification/training expirations and send notifications to complete training.

- Create individual dashboards and training reports for managers and employees, improving accessibility of training expectations and records.

- Demonstrate compliance with regulatory requirements for training.

Technology Used

- SharePoint to store the training data

- PowerApps to record and manage course information

- Power Automate for email notifications