Food Safety / Safety

Comments: No Comments

Safety hazards exist in every manufacturing environment. The food industry is no exception. Between October 2018 and September 2019, the Occupational Safety and Health Administration (OSHA) issued a total of 1,168 citations resulting in over $7 million in fines to the food manufacturing industry alone.

Occupational safety and health risks in food manufacturing are often heightened because of the nature of the product (i.e., food or drink) being manufactured. Even food safety measures taken to prevent contamination and ensure food safety can carry inherent occupational safety and health risks.

While food safety is paramount for any company operating in the food industry, a company cannot stay in business if they do not take the appropriate measures to keep employees healthy and safe.

Common Safety Hazards in the Food Industry

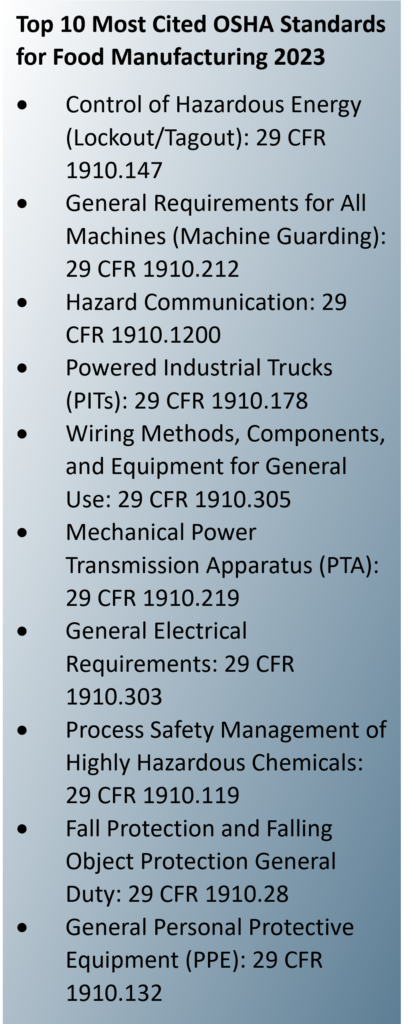

Lockout/tagout and machine guarding recurringly top OSHA’s annual list of the most frequently cited standards in food manufacturing. In fact, the most expensive OSHA fines of 2023 involved two food manufacturers and violations concerning machine guarding and lockout/tagout.

Lockout/Tagout

Employees need to be protected against the unexpected startup or release of energy. Lockout/tagout involves properly de-energizing and securing equipment so it cannot be operated unsafely when a machine needs service or repair. When employees work in a fast-paced environment, they may not take the required steps to first properly de-energize the equipment. As a result, approximately 1,000 workers die each year due to unexpected operation of equipment and/or release of stored energy. Machines and electrical equipment must be properly shut down, de-energized, and locked when servicing.

Machine Guarding

Moving machine parts have the potential to cause severe workplace injuries, such as crushed fingers or hands, amputations, burns, blindness—and most food processing machinery includes pinch points (i.e., blades, rolling parts, presses, etc.) that can put workers at increased risk. Safeguards for machine parts, functions, and processes are essential for controlling hazards and protecting workers from these otherwise preventable injuries.

Other Common Safety Hazards

- Ergonomics. Many food manufacturing jobs involve repetitive motion that can cause musculoskeletal disorders.

- Slips, trips, and falls. Sticky or wet products and frequent cleaning can both contribute to slippery work surfaces that increase the risk for slips, trips, and falls. The high volume of liquids used in food manufacturing and processing creates regular employee exposure to wet surfaces.

- Chemicals and harmful substances. Food facilities rely on various chemical sanitizers and disinfectants to prevent contamination. In addition, anhydrous ammonia, a common refrigerant used in food facilities, is very hazardous (i.e., corrosive, flammable, and explosive), even in small spaces.

- Cut hazards. Knives and other blades are common equipment in food processing plants. Dull blades cause more accidents because they are harder to work with, require more pressure, and may slip more easily. Blades should be sharpened, and employees should wear appropriate PPE.

OSHA Response: Local Emphasis Programs

Between 2016 and 2020, OSHA investigated fatalities, amputations, fractures, and crushed hands and fingers at food manufacturing facilities and identified the primary causes as failure to control hazardous energy or implement adequate machine guarding. In Wisconsin, Bureau of Labor and Statistics (BLS) data from 2011-2020 show that food manufacturing injury rates were consistently higher than the averages for all Wisconsin manufacturing companies. In 2019, OSHA found that food production workers in Ohio had a nearly 57% higher rate of amputations and 16% higher rate of fractures; in Illinois, these rates were 29% higher for amputations and 14% higher for fractures compared to private sector manufacturing.

In 2022, OSHA Region 5 established two Local Emphasis Programs (LEPs)—one for Wisconsin and one for Illinois and Ohio— to encourage employers to identify, reduce, and eliminate exposure to machine hazards during production activities and off-shift sanitation, service, and maintenance tasks (i.e., machine guarding and hazardous energy control – lockout/tagout). These LEPs run through at least 2027 and focus on reducing fatalities and injuries through outreach, education, training, and enforcement activities.

The LEP empowers OSHA to schedule and inspect food industry employers whose injury rates exceed the state average among all manufacturers. The scope of inspections conducted under the LEP focus on reviewing:

- Production operations, sanitation processes, and working conditions.

- Injury and illness records (i.e., OSHA 300 logs), particularly injuries pointing to deficiencies in machine guarding or the hazardous energy control program.

- Machine guarding hazards associated with points of operation, ingoing nip points, and moving or rotating parts of food processing equipment.

- Deficiencies in the hazardous energy control program associated with equipment service, maintenance, setup, and sanitation.

- Hazards associated with chemical burns from corrosives, such as those used for cleaning and sanitizing.

Prepare Your Facility…Protect Your Workers

If you fall under an OSHA LEP, you need to prepare your facility. Even if you don’t, you need to protect your workers.

- Prepare and maintain your OSHA 300 log with any work-related injuries and illnesses. KTL’s OSHA 300 PowerApp can make it easier to collect, search, analyze, store, and aggregate data so it is available when needed.

- Conduct a thorough hazard analysis of the facility, operations, and processes to identify potential safety hazards. The hazard analysis should answer what could potentially go wrong, what the associated consequences are, and how they can be prevented or eliminated.

- Develop, implement, and maintain the appropriate safety programs, procedures, and instructions. A safety management system that aligns with current food safety systems can provide resources to help companies identify and manage safety risks and an organizing framework for policies, procedures, and practices, including:

- Engineering controls for dangerous equipment, including machine guarding.

- Written energy control program and lockout/tagout procedures specific to each piece of equipment.

- Emergency response programs.

- Proper maintenance, cleaning, and sanitation procedures and schedules.

- Guidelines for proper use, care, and replacement of PPE.

- Train your staff. Workers need to have appropriate training, including use of PPE, hazards of extreme temperatures, material handling, hazard communication, lockout/tagout procedures, machine guarding procedures, etc. Initial safety training should be conducted when onboarding new employees, with refresher training provided annually to ensure competency. Training tracking systems allow for the centralized implementation, management, tracking, scheduling, assignment, and analysis of organizational training efforts.

- Provide proper PPE. Workers should be wearing proper footwear, gloves, safety glasses, ear plugs, aprons, etc. and be provided with anti-slip mats to ensure safety.

- Ensure safety data sheets (SDS) are current and available to help identify hazardous chemicals and protect employees from exposure. Train workers on the chemicals used in the workplace, including first aid, what to do in the event of a release, identifying characteristics, proper procedures for working around or with the chemical, and appropriate PPE.

- Use visual communication (e.g., labels, signage) to help protect workers from hot surfaces, exposed moving parts, pressurized systems, hazardous chemicals, slippery surfaces, and more.

Finally, prioritize safety. Small steps can go a long way in making sure employees leave work safely versus becoming an OSHA statistic.