KTL to Present at MECC 2023 on Energy Audits & Compliance Management Systems

KTL is excited to be joining the 2023 Midwest Environmental Compliance Conference (MECC) in Overland Park, Kansas, September 26-27, 20023 as a featured presenter. MECC takes a fresh, regional approach to the increasingly difficult task of environmental compliance, permitting, enforcement, and other critical environmental issues that impact Midwest facilities and institutions.

KTL’s presentions are part of the workshop’s technical agenda:

What is an energy audit—and why you should do one

September 26, 2023 | 12:30 pm | Coulter Wood, CEM, CPEA, Senior Consultant

Want to reach your sustainability goals, improve your energy efficiency, and save money? Learn what an energy audit is, how it can help you better understand your energy usage and issues, and how you can leverage your audit to identify opportunities to create energy efficiencies and reduce your carbon footprint.

The big secret: you already have the software you need to manage EHS programs

September 27, 2023 | 9:35 am | Joe Tell, Principal

Implementing software to manage EHS compliance sounds expensive, but it doesn’t have to be—not when most companies already have the software they need. See how to leverage the Microsoft Power Platform® to elevate EHS and effectively manage compliance documentation and data.

Integrated Emergency Response Plans

The most effective way to respond to an emergency is to properly plan for it before it happens. That’s precisely why so many federal, state, and municipal laws and regulations require many facilities to develop and implement some sort of Emergency Response Plan (ERP).

Effective Emergency Response

An ERP is intended to outline the steps an organization needs to take in an emergency—and after—to protect workers’ health and safety, the environment, the surrounding community, and the business itself. The requirements developed by various agencies are important, as they establish the components that must be included in an ERP to comply with regulations and respond effectively.

Most ERPs contain the same basic information. However, it can get complicated when a facility is subject to more than one regulation requiring an ERP, because even though the various regulations share many similarities, they also contain important differences (e.g., command structures, training requirements, equipment needs, operating protocols). Often, facilities end up creating a different ERP to respond to the different regulatory requirements. In an actual emergency, this can create inconsistencies or, worse yet, an implementation nightmare trying to figure out which ERP to follow.

Importance of Integration

The solution lies in integration. For example, consider an integrated management system that allows organizations to align standards, find common management system components (e.g., terminology, policies, objectives, processes, resources), and add measurable and recognizable business value. The same can be done with the various ERPs required within a facility.

It shouldn’t come as a surprise that in 1996, the U.S. National Response Team (NRT) published initial guidance for consolidating multiple ERPs into one core document. The Integrated Contingency Plan (ICP or One Plan) is a single, unified ERP intended to help organizations comply with the various emergency response requirements of the Environmental Protection Agency (EPA), U.S. Coast Guard, Occupational Safety and Health Administration (OSHA), Department of Transportation (DOT), and Department of Interior (DOI). The ICP Guidance does not change any of the existing requirements of the regulations it covers; rather, it provides a format for consolidating, organizing, and presenting the required emergency response information.

While the ICP does not currently incorporate all federal regulations addressing emergency response, it does establish a basic framework for organizations to pull in ERPs for any applicable regulations. And the benefits of doing so are many:

- Streamlined planning process. A single document simplifies the planning, development, and maintenance process. When plans are integrated, it minimizes duplication of effort, eliminates discrepancies and inconsistencies, and helps the organization identify and fill in gaps.

- Improved emergency response. It is much easier—and faster—for emergency responders and employees to navigate one plan rather than multiple separate ones. One plan allows for a single command structure with defined roles rather than potentially conflicting responsibilities. This all allows responders to act quickly and decisively to minimize potential disruption to the organization and public.

- Greater compliance. An integrated ERP provides improved visibility to all parts of the organization’s emergency response and helps reveal gaps that could prove costly and/or dangerous. This is especially important for organizations that must comply with several regulations.

- Potential cost savings. Streamlined and simplified planning reduces the resources required to build the plan. An integrated ERP may also help eliminate regulatory fines and minimize the need for and associated costs of emergency response/cleanup efforts.

Find Your Format

The goal of an integrated ERP is not to create new requirements but to consolidate existing concepts into a single functional plan structure. Regardless of what the plan looks like, it should start with:

- An assessment of the facility’s vulnerabilities to various emergency situations.

- An understanding of the various applicable emergency planning laws and regulations to determine which specific requirements must be incorporated. For example, food emergency response has different implications that must be integrated, particularly when it comes to recovery. A food production facility that is ordered or otherwise required to cease operations during an emergency may not reopen until authorization has been granted by the regulatory authority. Food facilities also have strict guidelines to follow for salvaging, reconditioning, and/or discarding product.

With this understanding, the ERP should then comprise step-by-step guidelines for addressing the most significant emergency situations. The core plan should be straightforward and concise and outline fundamental response procedures. More detailed information can be included in the annex. Most ERPs should include the following basic elements:

- Facility information. Consolidate common elements required in various plans, including site description, statement of purpose, scope, drawings, maps, roster of emergency response personnel, emergency response equipment, key contacts for plan development and maintenance, etc.

- Steps to initiate, conduct, and terminate a response. Outline essential response actions and notification procedures, with references to the annex for more detailed information. Provide concise and specific information that is time-critical in the earliest stages of the response and a framework to guide responders through key steps to deliver an effective response.

- Designated emergency responders. Develop a single command structure for all types of emergencies. Assign qualified, high-level individuals who are familiar with emergency procedures to fill emergency roles. In addition, list the appropriate authorities for specific emergencies, as well as their contact information.

- Evacuation plan/routes and rally points. Clearly mark evacuation routes and identify rally points where employees should meet upon exiting. Do not allow employees to leave designated rally points until it has been documented they have safely left the building.

- Data and information backup technology. Develop provisions for data backup to secondary/off-site systems, as well as alternate options for communications and power.

- Designated plan for communication. Outline who is communicating what, when they are communicating it, and how it is being communicated. This includes internal communication, as well as communication to customers/clients/suppliers/vendors that may be impacted, the media, and the appropriate regulatory authorities.

- Supporting materials. The annex should provide detailed support information based on the procedures outlined in the core plan and required regulatory compliance documentation. Importantly, facilities should create a table that cross-references individual regulatory requirements with the plan to ensure there are no gaps and to demonstrate compliance.

Ensuring Success

The goal of emergency response planning is to minimize impacts to the environment and workers’ health and safety, as well as disruptions to operations. An integrated ERP has the potential to significantly reduce the number of decisions required to respond in an emergency, eliminate confusion and disagreement regarding roles and responsibilities, and enable a timelier, more coordinated response.

That all being said, an integrated ERP will only be effective if it is thoroughly and consistently communicated to all employees. These best practices will help ensure that the integrated ERP functions not only on paper, but also in practice:

- Periodic training is vital to ensure employees understand the ERP and are fully aware of emergency response procedures. It is especially important in an integrated ERP that first responders are trained to handle all potential emergencies rather than more narrowly trained on response for a single regulation.

- Routine drills significantly improve understanding of the ERP, clarify employee roles, test procedures to ensure they work, and diminish confusion during an emergency.

- Posting an abbreviated version of the ERP throughout the plant provides easy access to all employees if an emergency occurs. This summary version of the ERP should highlight the most vital information for quick response: recognized hazards, high-level emergency procedures, evacuation routes, and key contacts.

Comments: No Comments

Earth Day 2023: Invest in Our Planet

Every year on April 22, Earth Day celebrates the birth of the modern environmental movement. The very first Earth Day—spearheaded by Senator Gaylord Nelson in 1970—led to the creation of the U.S. Environmental Protection Agency (EPA) and the passage of new environmental laws, including the National Environmental Education Act, the Occupational Safety and Health Act, and the Clean Air Act.

While the early Earth Days concentrated on enacting legislation to clean up environmental concerns, Earth Day today is largely focused on what we can do to sustain our planet for future generations…

Creating a Green Future

The EARTHDAY.ORG 2023 theme picks up from last year—”Invest in Our Planet”—and is focused on engaging governments, institutions, businesses, and citizens to do their part: everyone accounted for, everyone accountable. According to Kathleen Rogers, President of EARTHDAY.ORG, “Businesses, governments, and civil society are equally responsible for taking action against the climate crisis and lighting the spark to accelerate change towards a green, prosperous, and equitable future.”

Government Initiatives

Governments around the globe have enacted many significant green policy initiatives, yet nearly every country in the world is not on track to meet greenhouse gas (GHG) neutrality by 2050, according to EARTHDAY.ORG.

The EPA released its most recent EPA Perspective: 5 Ways EPA is Protecting People and the Planet in honor of Earth Day. The Agency cites the following key areas the U.S. government is concentrating on to positively impact our planet:

- Tackling the climate crisis with the urgency it demands, including technology standards for cars and trucks and funding for local governments to cut climate pollution.

- Confronting longstanding environmental injustices and inequities, through investments in EPA’s environmental justice (EJ) initiatives to fund and support programs to reduce pollution and improve public health, particularly in historically underserved communities.

- Improving air quality in neighborhoods across the country with several action to cut harmful air pollution and smog from power plants and industrial facilities.

- Ensuring clean water for all families through President Biden’s Investing in America agenda, which invests billions in rebuilding our nation’s water infrastructure, and by proposing the first-ever legal limits for PFAS in drinking water.

- Building a healthier future, from the Clean School Bus Program to accelerate a zero-emission transportation future, to starting new cleanup projects at 22 Superfund sites.

What You Can Do

Governments, businesses, and citizens are all essential in taking action to overcome the climate crisis. When it comes to your organization, EARTHDAY.ORG suggests, “Businesses, inventors, and financial markets must drive value for their institutions and society through green innovation and practices. Like other economic revolutions, the private sector has the power to drive the most significant change, with both the necessary scale and speed.”

Change starts with action. Learn more about how you can be part of Earth Day every day.

Comments: No Comments

Energy Management: Reviewing Your Utility Bill

Energy monitoring is a key first step in effective energy management, as it allows organizations to understand their energy consumption patterns and identify routine waste in the process. Reviewing utility bills is a basic initial action that can offer significant insights into how an organization consumes energy and what opportunities may exist for immediate and longer-term savings.

Uncovering Opportunities

Working with a Certified Energy Manager (CEM) to review and analyze a 12-month history of utility data for both electricity and natural gas can help identify peak demand, load profile, taxes, and historic trends in usage. This information can be used, in turn, to calculate savings on efficiency measures and projects based on utility costs. Such opportunities may include the following:

Tariff Review

A utility tariff governs how an energy provider (electric or natural gas) charges the customer for their electricity and natural gas usage. Utilities set out the rates, terms, and conditions of service in these tariffs. Electricity tariffs can vary widely by location and provider, hence the importance of reviewing the organization’s current tariff with its energy provider.

After reviewing utility bills and preparing a profile of energy usage, it is possible to compare the current tariff with other available tariffs to determine if there is a more cost-effective way to purchase energy. The utility may conduct these tariff reviews on your behalf; however, a second opinion can often identify savings opportunities to take advantage of the way a tariff may be structured. For example, a portion of the total utility bill is typically determined by actual demand and structure of the tariff. Where demand charges are nearing 50% of the bill, there are often opportunities for cost savings, including:

- Shifting production to take advantage of lower rates in off-peak hours or seasons.

- Staggering startups to reduce instantaneous demand.

Tax Exemption

If you are paying the full taxes on your electricity and natural gas, your organization may be eligible for a tax exemption depending on where the facility is located. The tax exemption typically applies to energy (gas or electric) that is used to manufacture saleable goods. Tax exemptions often apply to 75% to 99% of the facility’s total utility tax burden.

To receive the exemption, an energy tax study is required to determine how much energy at the facility is used in the manufacture of saleable goods (i.e., any processes that modify the product) versus the energy used for ancillary operation (e.g., warehousing, welfare spaces, lighting). Typically, these studies must be renewed when significant changes occur at the facility to impact load or every three years, whichever is soonest (depending on state-specific rules). The value of the tax emption can vary greatly depending on facility size.

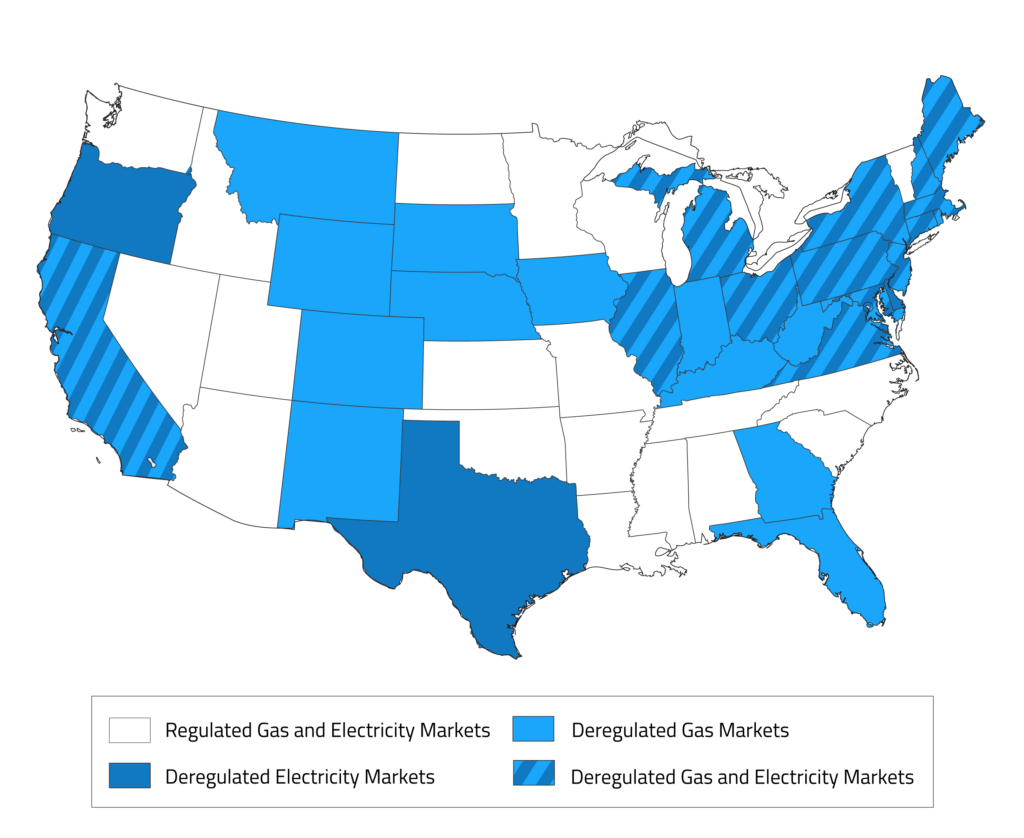

Energy Costs in the Open Market

Energy costs (gas and electric) can be compared against known market rates to determine whether there may be an opportunity for cheaper supply on the open market. The map below shows which states have a deregulated energy market. Any operations in these states may be able to find partnerships with third-party energy suppliers for cost savings.

Utility bills are just a starting point. The more data that can be reviewed and analyzed—and the more detailed it is—the easier it is to identify cost- and energy-saving opportunities within operations.

KTL has experience reviewing utility bills and helping organizations of all sizes identify energy consumption patterns and energy efficiency solutions. Please contact us for assistance in meeting your energy, environmental, and sustainability objectives.

Comments: No Comments

Q&A with KTL’s Certified Energy Manager (CEM)

According to the International Energy Agency (IEA)’s World Energy Outlook 2022, “The world is in the midst of the first truly global energy crisis, with impacts that will be felt for years to come” due to energy shortfalls and high prices of natural gas and coal—much related to Russia’s invasion of Ukraine. The Outlook further states that advanced economies/governments have committed well over $500 billion to protect consumers, but the key takeaway from IEA is clear: “Today’s energy shock is a reminder of the fragility and unsustainability of our current energy system.”

Greater energy efficiency is a key part of the solution—and not just at a federal level. With significant government policies and pledges to achieve a NetZero Economy by 2050, organizations large and small need to be thinking about energy management. What does this mean? KTL Senior Consultant and Certified Energy Manager (CEM) Coulter Wood answers a few questions to offer some insight.

What is energy management?

Energy management involves monitoring and controlling energy consumption across an organization to save energy and, subsequently, save money. Energy management should be part of the overall strategy of a company, with the ultimate objective of reducing the cost of energy (i.e., creating energy efficiencies) without impacting work processes or products.

The energy management process involves four key steps:

- Collect and analyze energy usage data. The more data—and the more detailed it is—the easier it is to identify energy waste within operations. Often, your local utility or energy provider is a good source for this type of data.

- Identify opportunities to improve energy efficiency and optimize energy usage. The easiest and most cost-effective energy-saving opportunities often require little capital investment.

- Implement energy optimization solutions. Gaining cross-functional support is key to realizing a return on investment.

- Track and monitor progress/results through an established “measurement and verification” process. Demonstrate results to garner additional support, adjust solutions, as needed, and repeat.

Why should companies be concerned with energy management?

Sound energy management practices can have many benefits to organizations:

- Reduce costs: The Carbon Trust estimates that most businesses can cut their energy costs by at least 10% (often by 20%) with simple actions that offer a quick return on investment. Operating more efficiently reduces energy consumption, which equates to significant savings on utility bills. This is particularly important as energy costs reach all-time highs.

- Reduce carbon emissions: The equation is simple: the less energy you use, the fewer carbon emissions you produce.

- Reduce risk: Organizations that consume significant amounts of energy are at greater risk of being impacted by energy price increases or supply shortages. When an organization can reduce its demand for energy, it also reduces the risks associated with an energy shortage. Having greater control over energy consumption creates resiliency against energy price fluctuations.

How does energy management relate to sustainability?

On a global level, energy consumption is the major contributor to climate change, making up nearly 60% of the world’s greenhouse gas (GHG) emissions. Consuming less energy, finding more energy efficient solutions, and/or using alternate renewable energy sources help to reduce energy consumption, reduce carbon emissions, reduce dependence on fossil fuels, and reduce the damage being done to the planet. This ties directly to sustainability goals, including carbon neutral incentives, and helps promote a strong environmental, social, and governance (ESG) image.

What about ISO 50001?

As part of the ISO family of management system standards, ISO 50001:2018 focuses on Energy Management Systems as a strategic tool to help organizations better manage their energy use and:

- Improve productivity.

- Reduce environmental impact.

- Enhance corporate reputation.

- Drive down costs.

- Improve competitiveness.

According to ISO, “ISO 50001 is designed to help organizations improve energy performance by making better use of its energy-intensive assets.” Like other ISO standards, ISO 50001 follows the plan-do-check-act (PDCA) process for continual improvement. This involves:

- Developing and implementing an energy policy.

- Setting achievable targets for energy use.

- Designing action plans to reach objectives (e.g., implementing energy-efficient technologies, reducing energy waste, improving current processes to cut energy costs).

- Measuring progress.

How do I get started?

Energy monitoring is a key first step in effective energy management, as it allows organizations to understand their energy consumption patterns and identify routine waste in the process. A basic initial action is to work with a CEM to review and analyze your utility bill (a 12-month history is ideal). This action alone can offer significant insights into how your organization consumes energy and what opportunities may exist for immediate savings.

Once you have a comprehensive understanding of how energy is being consumed, it becomes possible to identify inefficiencies and opportunities for improvement, whether related to behavior (e.g., asking employees to turn off lights every night), technology (e.g., implementing integrated building management systems), or process (e.g., increasing operations during off-peak hours).

KTL has experience reviewing utility bills and helping organizations of all sizes identify energy consumption patterns and energy efficiency solutions. Please contact us for assistance in meeting your energy, environmental, and sustainability objectives.

EHS Trends to Watch in 2023

Every year, we see a number of environmental, health, and safety (EHS) trends rise to the surface that have the potential to impact many industries. Some challenges and opportunities in EHS remain ongoing; some are just gaining traction with impacts yet to be known. Regardless, the start of a new year provides the opportunity to plan for EHS issues and trends on the horizon and prioritize efforts to ensure ongoing compliance.

Here are some of the top EHS trends KTL is keeping watch on in 2023—and some guidance to help you as you set your EHS strategy for the new year.

Resource Constraints and Technology Solutions

EHS personnel are being asked to manage a lot—and often in growing areas that may be outside their education, expertise, and/or experience. Resource constraints—particularly related to staffing—remain a significant concern across industry, and EHS is certainly not immune. Impacts from the “Great Resignation” of November 2021 and beyond continue to leave many companies without the resources needed to effectively manage EHS requirements.

Achieving and maintaining EHS compliance requires great management and expertise to ensure all aspects of a company’s technical compliance have been identified and are being actively handled. KTL has been working with more and more EHS departments to fill these gaps—either with outsourced personnel or compliance efficiency tools—as companies look to recruit EHS staff and meet compliance obligations.

Guidance:

- Develop a relationship with someone you trust to do things in your best interest, understanding that EHS should be a process of continuous improvement. Use them to help you understand what regulations apply. Let them help you prioritize your compliance plan. Use them to do your annual training. Rely on them as a part of your team.

- Employ information technology (IT) solutions to create compliance efficiencies. A well-designed and executed compliance information management system brings IT and management systems together to coordinate, organize, control, analyze, and visualize information in such a way that helps organizations remain in compliance and operate efficiently. A system like this will help provide operational flexibility, generate business improvement, and prepare organizations to address these and other EHS compliance challenges that will continue to surface.

EPA Inspections and Enforcement

EPA intends to continue its enforcement path, holding environmental violators and responsible parties accountable. Significant investments are being made to enforce and ensure compliance with the nation’s environmental laws, including $213 million for civil enforcement efforts, $148 million for compliance monitoring efforts, and $69 million for criminal enforcement efforts. The Agency also has plans to improve inspections by sending 75% of EPA inspection reports to facilities within 70 days of inspection and conducting 55% of annual EPA inspections at facilities that affect communities with potential environmental justice (EJ) concerns (see more on EJ below).

Guidance:

- Design and maintain a safe facility to prevent accidental releases and minimize the consequences of accidental releases that do occur. Conduct a gap assessment to ensure the required processes and systems are functioning as intended.

- Establish a quick response internal inspection team that can evaluate all areas of risk in your facility to ensure you are in compliance, particularly at the time of inspection.

- Understand the hazards posed by chemicals at the facility and assess the impacts of a potential release. Complete a waste characterization for all hazardous and solid waste streams to make sure you are appropriately managing your universal waste and hazardous waste.

- Check your Emergency Response Plan to ensure it has identified emergency contacts for your facility and that the contacts are current. Coordinate with local emergency responders.

Environmental Justice (EJ)

EPA’s Strategic Plan includes a goal that EJ and civil rights will be embedded into EPA’s programs, policies, and activities to reduce disparities in environmental and public health conditions. This focus on EJ has continued to gain momentum with a slew of additional significant actions taken in 2022 to further elevate EJ priorities and deliver on the Administration’s promises to advance justice and equity when it comes to ensuring clean air and water for all communities; safeguarding and revitalizing communities (i.e., Superfund and RCRA); and ensuring safety of chemicals through civil rights and compliance reviews, audits, and community outreach.

Guidance:

- Take the time to understand the communities where you operate—be informed, be prepared, and be proactive. Establish companywide priorities and goals and commit the appropriate resources to address EJ concerns.

- There are a number of EJ grants, funding, and other technical assistance available. EPA’s new Office of Environmental Justice and External Civil Rights is positioned to deliver new grants and technical assistance to meet EJ goals.

Sustainability and Climate Change

The Biden Administration previously committed to a net zero economy by 2050. EPA is focused on reducing greenhouse gas (GHG) emissions by promulgating rules to reduce pollution from the power sector, setting vehicle emission standards, and partnering with the public and private sectors communities (especially those underserved and disproportionally at risk) to increase energy efficiency in the residential, commercial, and industrial sectors. In addition, there is $100 million in grants to support efforts to reduce GHG emissions and increase resiliency in the nation’s infrastructure and $35 million to implement the American Innovation in Manufacturing Act to continue phasing out GHGs.

Guidance:

- Conduct a lifecycle analysis (LCA) to identify and quantify the inputs and outputs in a process and use data to assess the potential environmental impacts across the lifecycle.

- Have an energy audit completed of your facilities.

- Get input from employees on what initiatives are important to them by enacting a sustainability committee or adding sustainability to your EHS agenda.

Safer Communities by Chemical Accident Prevention (SCCAP)

EPA proposed on August 31, 2022 to strengthen the Risk Management Program (RMP) regulations with the SCCAP proposed rule. The proposed SCCAP amendments include a number of requirements that were originally promulgated by the Obama Administration EPA in 2017 and subsequently rescinded during the Trump Administration in 2019, plus several new requirements considering impacts of climate change, EJ concerns, employee participation, and enhanced community notification. Proposed changes would require RMP-regulated facilities to better consider surrounding communities and the consequences of potential chemical accidents that could have significant impacts on industry requirements going forward.

Guidance:

- Identify/understand/prioritize your compliance risks and develop strategies to minimize them to the extent possible.

- Outline steps to improve performance and safe operations, including defining organizational roles and responsibilities. Plan and conduct required tabletop exercises and coordinate with Local Emergency Planning Committees (LEPCs) to ensure your plans work in practice.

- Streamline compliance methods and improve operational efficiencies by implementing IT solutions and compliance management systems that coordinate, organize, control, analyze, and visualize information.

PFAS Contamination

More and more facilities are going to be directly impacted by mitigation efforts and future regulatory action related to per- and polyfluoroalkyl substances (PFAS). PFAS contamination is an extremely complicated issue—and concern is mounting over its impacts and how to regulate these chemicals going forward. EPA has set aside $126 million to increase its understanding of human health and ecological effects of PFAS contamination, restrict its uses, and remediate PFAS that have been released. Over the course of 2022, EPA took several actions to further protect individuals and communities from the health risks posed by these forever chemicals and more is on the way.

Guidance:

- Evaluate your current environmental risk level and develop strategies to minimize risks to the extent possible. Proper usage strategies, a comprehensive environmental management system (EMS), and a forward-thinking Emergency Response Plan will remain vital tools for companies potentially dealing with PFAS to effectively manage the associated risks.

- Work with LEPCs to coordinate emergency response efforts and exercises to keep communities informed and safe.

Set Your Goals for 2023

With these trends toward more regulation, more enforcement, and more focus on EJ and sustainability—but with fewer resources to manage it all—companies need to accurately assess compliance requirements and create a plan for how to meet them. KTL suggests completing the following early in 2023:

- Get senior leadership commitment. It is often clear how an organization prioritizes EHS with little digging. Even with the best EHS personnel, the organization and its EHS system will only be as good as the top leadership and what is important to them.

- Conduct a comprehensive gap assessment to ensure you are meeting the requirements of all applicable EHS regulations. This should be the starting place for understanding your regulatory obligations and current compliance status.

- Perform a comprehensive onsite risk assessment with associated risk minimization planning and plan/conduct annual spill drills to practice emergency response for hazardous chemical incidents.

- Organize your records. Know what records you need. Document your inspections and your training. Develop standard operating procedures (SOPs) so people know what to do.

- Create an integrated management system (e.g., ISO 9001/14001/45001) by finding commonalities between the standards and leveraging pieces of each to develop a reliable system that works for your organization. Implement IT solutions to streamline compliance and create business efficiencies.

- Seek third-party oversight. Having external experts periodically look inside your company provides an objective view of what is really going on, helps you to prepare for audits, and allows you to implement corrective/preventive actions that ensure compliance.

Comments: No Comments

Recent Advances in Environmental Justice

“Far too many of our most disadvantaged Americans continue to live in communities where clean water clean air, and a healthy environment aren’t a reality.” ~ Senator Tom Carper, Chair of Senate Committee on Environment and Public Works (DE).

Environmental justice (EJ) seeks to provide “fair treatment and meaningful involvement of all people regardless of race, color, national origin, or income, with respect to the development, implementation, and enforcement of environmental laws, regulations, and policies” (U.S. Environmental Protection Agency – EPA).

Almost immediately upon taking office, the Biden-Harris Administration took swift and significant action to promote EJ efforts. Executive Order (EO) 13990 Protecting Public Health and the Environment and Restoring Science to Tackle the Climate Crisis and EO 14008 Tackling the Climate Crisis at Home and Abroad both direct federal agencies to develop EJ strategies to address the disproportionately high and adverse human health or environmental impacts of their programs on minority and/or low-income populations. The Justice40 Initiative has made it a goal that 40 percent of the overall benefits of certain federal investments are funneled to disadvantaged communities overburdened by pollution. And EPA’s FY 2022-2026 Plan added a fourth principal to support Biden’s Justice40 initiative—advance justice and equity—and states that “EJ and civil rights will be embedded into EPA’s programs, policies, and activities to reduce disparities in environmental and public health conditions.”

Growing Momentum

The focus on EJ continues to gain momentum with a slew of additional significant actions taken recently to further elevate EJ priorities and deliver on the Administration’s promises to advance justice and equity.

Inflation Reduction Act

On August 12, 2022, the Inflation Reduction Act (IRA) of 2022 passed. The IRA grants funding to EPA to help accelerate EJ efforts in the following areas.

| Area | Funds | Action/Objective |

| Greenhouse Gas (GHG) Reduction Fund | $27 billion | Provide financing to support GHG reduction projects in low-income and disadvantaged communities. |

| Environmental and Climate Justice Block Grants | $3 billion | Empower community efforts and advance EJ projects (e.g., community-led air pollution monitoring, prevention, and remediation; mitigating climate and health risks from extreme heat and wildfires; climate resiliency and adaptation; and reducing indoor air pollution). |

| Protecting Children | $50 million | Provide grants and technical assistance to schools serving low-income communities to address environmental issues, develop school environmental quality plans, mitigate air pollution hazards, and improve health and safety for students and staff. |

| Clean Ports | $3 billion | Provide funding for zero-emission port equipment/technology and to help ports develop climate action plans. |

| Superfund Petroleum Tax | $11.7 billion | Reinstate the Superfund petroleum tax to help ensure polluters are held accountable for the true cost of cleanup work. |

| Enforcement Technology | $25 million | Hold polluters accountable by improving enforcement technology; target enforcement on several of the nation’s environmental laws (e.g., Clean Water Act (CWA), Clean Air Act (CAA), Resource Conservation and Recovery Act (RCRA)). |

| Cleaner Emissions from Trucks and Heavy-Duty Vehicles | $1 billion | Support a zero-emission vehicle infrastructure. |

New EPA Office of Environmental Justice and External Civil Rights

On September 24, 2022, EPA announced a new national Office of Environmental Justice and External Civil Rights to help elevate EJ to the highest levels of government. According to EPA, this office will commit more than 200 staff in EPA headquarters and across 10 regions to help solve environmental challenges in underserved communities. The intent of this office is to:

- Improve EPA’s ability to incorporate equity, civil rights, and EJ principles and priorities into all EPA practices, policies, and programs.

- Support the fair treatment and meaningful involvement of all people in development, implementation, and enforcement of environmental laws, regulations, and policies.

- Engage communities with EJ concerns and increase support for community-led action through grants and technical assistance.

- Enforce federal civil rights laws that prohibit discrimination based on race, color, or national origin; sex; disability; or age by applicants for and recipients of EPA federal financial assistance.

- Provide services and expertise in alternative dispute resolution, environmental conflict resolution, consensus building, and collaborative problem solving.

The new office will ensure that implementation of the IRA’s funding programs meet the Justice40 Initiative. Office staff will also work with the Office of Land and Emergency Management to equitably carry out EPA’s final EJ Action Plan (see below).

Environmental Justice Action Plan for Land Protection and Cleanup Programs

September 30, 2022, EPA announced its finalized EJ Action Plan: Building Up Environmental Justice in EPA’s Land Protection and Cleanup Programs (EJ Action Plan). The plan outlines projects, tools, and practices to be applied to the Superfund, Brownfields, Emergency Response, Solid Waste Management, RCRA Corrective Action, and Underground Storage Tank (UST) programs to improve the quality of cleanups in communities with EJ concerns.

The EJ Action Plan is supported by Bipartisan Infrastructure Law investments, including $1 billion to initiate cleanup of 49 previously underfunded Superfund sites and accelerate cleanup at dozens of other sites.

EPA states four main goals for the EJ Action Plan:

- Strengthen compliance with cornerstone environmental statutes by developing a “Good Governance” process and referral list to help address communities’ ongoing environmental concerns.

- Incorporate EJ considerations during the regulatory development process by assessing impacts to pollution-burdened, underserved, and tribal communities when developing regulations and tools to identify, track, and consider the implications of EJ-related factors throughout the Superfund process.

- Improve community engagement in rulemakings, permitting decisions, and policies by providing earlier and more frequent engagement with pollution-burdened and underserved communities and increasing technical support and risk communication resources.

- Implement President Biden’s Justice40 Initiative through grant application resources and grant award decisions.

Improved Environmental Management

With EPA focused on more regulations, more enforcement, and improved climate change and EJ, environmental management needs to play an integral role in company strategy. Companies must take the time to be informed, be prepared, and be proactive. Establish companywide priorities and goals and commit the appropriate resources to ensure programs and systems are in place to achieve regulatory compliance and align with EPA’s priorities for the future.

If you would like help evaluating your current risk level and assessing your priorities, please contact KTL.

2022 CAPPA Conference: KTL Case Study on Managing EHS Compliance

The Central region of APPA (CAPPA) is back hosting the 2022 Annual Conference in Lincoln, Nebraska this October–and KTL is looking forward to being part of the technical agenda this year! With the constant state of change in Higher Education, every interaction with students, faculty, staff and our business partners, vendor, etc. is important to improvement and growth in facilities. This year’s conference is filled with business and educational sessions to help support facilities management professionals in educational institutions.

KTL will be joining Southeast Missouri State University’s Autumn Gentry to present the following case study:

Using Microsoft 365 and SharePoint® to Manage EHS Compliance: University Case Study

October 10, 2022 | 11:00-11:55 a.m.

This presentation will discuss how educational facilities can use Microsoft 365 and SharePoint as a tool to manage EHS compliance programs. We will provide an overview of applicable EHS regulations, discuss how 365/SharePoint can be used to address university-specific needs, and provide a demonstration of Southeast Missouri State University’s “live” EHS management system.

Comments: No Comments

Progress on PFAS

On October 18, 2021, the Environmental Protection Agency (EPA) announced its comprehensive Strategic Roadmap to tackle per- and polyfluoroalkyl substances (PFAS) contamination. The roadmap focuses on increasing investments in research, leveraging authorities to act now to restrict PFAS chemicals from being released, and accelerating cleanup of PFAS contamination.

Under this roadmap, more and more facilities are starting to be directly impacted by mitigation efforts and pending regulatory action. Just recently, EPA took the following actions to protect individuals and communities from the health risks posed by these “forever chemicals”.

Proposed Hazardous Substances Under Superfund

On August 26, 2022, EPA has issued a proposal to seek public comment on designating two of the most widely used PFAS as hazardous substances under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA, aka Superfund). This proposal applies to perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS), including salts and structural isomers.

Like other PFAS, PFOA and PFOS can accumulate and persist in the human body for long periods of time. The intent of this rulemaking is twofold:

- Increase transparency around releases of PFOA and PFOS; and

- Help hold polluters accountable for cleaning up their contamination.

If finalized, the rulemaking would trigger reporting of PFOA and PFOS releases, providing the EPA with improved data and the option to require cleanups/recover cleanup costs. According to EPA, a release of PFOA, PFOS, or any other hazardous substance does not always add a site to the National Priorities List (NPL), necessitate cleanup, or result in an enforcement action.

EPA suggests this potential rulemaking would:

- Improve EPA, state, Tribal nation, and local community understanding of the extent and locations of PFOA and PFOS contamination throughout the country.

- Help communities avoid or reduce contact with these potentially dangerous chemicals.

- Encourage better waste management and treatment practices by facilities handling PFOA or PFOS.

- Potentially accelerate privately financed cleanups and mitigate potential adverse impacts.

- Allow EPA to recover cleanup costs from a potentially response party or require such a party to conduct the cleanup.

- Better protect public health.

EPA anticipates issuing an Advance Notice of Proposed Rulemaking in the next several weeks and will seek public comment once that is published.

Removal from Pesticide Products

On September 1, 2022, EPA proposed to remove 12 chemicals identified as PFAS from the current list of inert ingredients approved for use in pesticide products. Unlike active ingredients, inert ingredients are used to enhance pesticide effectiveness and product performance (e.g., extend shelf life, improve ease of application). EPA reviews safety information for inert ingredients before they can be included in a pesticide.

While these 12 PFAS are no longer used in any registered pesticides, EPA decided to remove the chemicals from the list of approved inert ingredients to prevent any further requested use in pesticide products.

EPA continues to evaluate pesticide active ingredients to determine if any meet the definition of PFAS or create other concerns.

Study on Leaching

In a recent study released on September 8, 2022, EPA confirmed that plastic containers made of fluorinated high-density polyethylene (HDPE) are likely to leach PFAS substances into pesticides and other liquid products that are stored in them. The data shows that the amount of PFAS that migrates into liquid products increases with storage time. This study further demonstrates the persistent and cumulative nature of PFAS.

Ongoing Challenges

KTL does not see the challenges associated with PFAS going away any time soon. If anything, we anticipate more facilities will be directly impacted by mitigation efforts and regulatory action to support the Strategic Roadmap, such as those outlined above. Proper usage strategies, a comprehensive environmental management system (EMS), and a forward-thinking Emergency Response Plan will remain vital tools for companies potentially dealing with PFAS to effectively manage the associated risks.

If you are facing challenges related to PFAS or would just like a fresh set of eyes to evaluate your current environmental risk level, please contact KTL. Our staff has hands-on experience assessing environmental risks and developing strategies to minimize them to the extent possible. Our team writes Emergency Response Plans and routinely works with Local Emergency Planning Committees (LEPCs) to coordinate emergency response efforts and exercises to keep communities informed and safe. In addition, we have a strong network of partners that can assist with testing and remediation strategies, when necessary.

KTL Expands EHS Resources

KTL is pleased to welcome the newest member of our EHS team!

Coulter Wood, CEM, CPEA, Senior Consultant

Coulter Wood, CEM, CPEA, is an is an environmental compliance and energy management leader with over 20 years of industry and consulting experience in providing expert regulatory and technical guidance, conducting energy and environmental compliance audits, leading corporate sustainability efforts and environmental capital expenditure projects, and managing energy sourcing and procurement. Coulter has extensive knowledge of state and federal environmental regulations. He has completed inspections and reports for emissions stack testing and Title V permitting, air emissions inventories, hazardous waste generation, storm water sampling, SPCC Plans, and NPDES authorizations and permits. He has also developed environmental and energy management systems. Coulter is a Certified Environmental Manager (CEM) and Certified Professional Environmental Auditor (CPEA). Coulter is based in Des Moines, Iowa. Read his full bio…

cwood@goktl.com | 507.208.9126