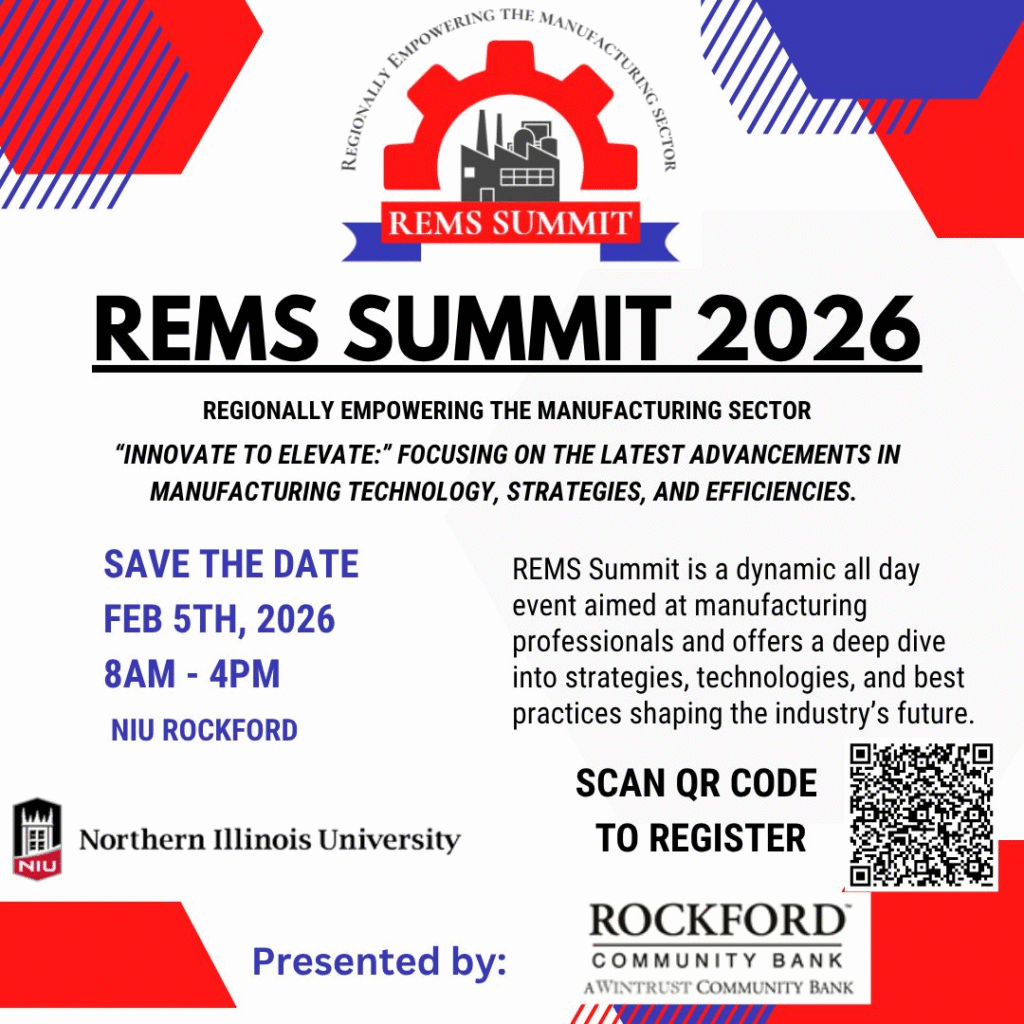

KTL to Present on EHS at REMS Summit 2026

If you are in the Rockford area, you won’t want to miss KTL at the REMS Summit 2026, held at the NIU Rockford Campus on February 5, 2026. The REMS Summit offers Rockford-area leaders in manufacturing keynote sessions on legislative updates and strategic priorities, as well as interactive breakout sessions covering workforce development, automation/AI, supply chain strategy, HR modernization, Lean leadership, and environmental, health & safety compliance.

KTL’s April Greene, CSP, CHMM, will be presenting a breakout session on Environmental, Health & Safety: What You Need to Know. This session will:

- Provide an overview of applicable federal, state, and local occupational safety and environmental regulatory requirements.

- Explain what is required to comply with federal, state, and local environmental and occupational safety regulations (i.e., your obligations as an employer).

- Identify common compliance pitfalls and gaps in existing operations, processes, and practices.

- Outline best practices for developing practical systems to manage risk and stay compliant.

Comments: No Comments

EHS Trends on the Horizon for 2026

As we move into 2026, the environmental, health, and safety (EHS) landscape is entering a period of heightened complexity and contradiction. Significant federal budget cuts and deregulation are reducing oversight from agencies like the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA), while state enforcement, investor expectations, global regulations, and public scrutiny continue to intensify. At the same time, emerging risks and opportunities (e.g., PFAS, water scarcity, AI-driven systems, data center projects) are reshaping how organizations must think about compliance, risk, and resilience. Here’s what KTL currently has on our radar for 2026.

EPA Budget Cuts

The EPA’s FY2026 budget is a 54% reduction from the FY2025 budget and its lowest in approximately 50 years. Not unexpectedly, this lack of funding is sharply reducing EPA’s planned enforcement capacity in 2026 across all major statutes, focusing enforcement efforts on “clear and substantial violations.” Major funding cuts include criminal enforcement (- 49%), civil enforcement (- 30%), compliance monitoring and inspections (- 35%), and Environmental Justice (EJ) enforcement (100% eliminated).

Despite federal inspections and enforcement sharply declining in 2026, organizations remain fully liable under the Clean Air Act, Clean Water Act, RCRA, TSCA, EPCRA, and CERCLA, and major incidents will draw intense scrutiny. While it may be tempting to let internal environmental programs and systems slide due to less federal oversight, dismantling internal EHS and Environmental Social Governance (ESG) systems may create higher long‑term risks, particularly as many states expand enforcement to fill the federal gap.

Tip: Treat proactive environmental management as an asset protection tool, not a regulatory cost. Preserve internal audit, monitoring, and corrective action programs; keep permit tracking, compliance calendars, and incident response processes intact; and maintain clear records and documents.

EPA Deregulation

Consistent with its budget cuts, the EPA has significant deregulation planned for 2026 focused largely on rolling back key climate‑related rules, including Vehicle Emission Rules and the Clean Power Plan 2.0, which regulates fossil fuel-fired power plants. In addition, the following rules are all on the proverbial chopping block:

Federal Greenhouse Gas (GHG) Reporting

The EPA is proposing to largely end mandatory federal GHG reporting beginning in 2026. If finalized as proposed, most industries would no longer be required to report GHG emissions under the GHG Reporting Program (GHGRP), and oil and gas industry reporting under Subpart W would be paused until 2034, with limited exceptions. Though federal reporting may disappear (unless tied to a clear statutory mandate), many state programs still rely on GHGRP‑style data; SEC, investor, and customer pressure for emissions disclosure is expected to continue; and lenders and insurers continue requiring verified emissions data.

Tip: Organizations that stop internal tracking may increase long‑term risk, particularly if future administrations reinstate reporting. Maintain internal GHG inventories and related transparency processes, and archive methodologies so reporting can restart without rebuilding systems.

Risk Management Program (RMP) Rule

Although the EPA has not yet issued a final rule, the Agency is reconsidering the Risk Management Program (RMP) requirements related to cross-agency coordination in the chemical transportation industry. This may include narrowing coordination requirements to onsite emergencies only, no longer requiring facilities to report accidents occurring off site during transport, eliminating mandatory sharing of RMP data with transportation regulators, and removing implied responsibility for transporter training verification, carrier safety management practices, and emergency preparedness beyond the facility.

Core RMP applicability remains and onsite transfer operations (loading/unloading) will still fall under RMP. Importantly, Emergency Planning and Community Right-to-Know Act (EPCRA) emergency planning obligations remain unchanged, state RMP programs are unaffected, and related OSHA Process Safety Management (PSM) and Department of Transportation (DOT) HazMat rules still apply independently.

Tip: Refine your chemical transportation risk management approach, as necessary, by remapping regulatory responsibility to the correct agency. Maintain strong DOT, OSHA, EPCRA, and contractual controls; preserve emergency preparedness; and continue sharing site‑specific emergency data with responders. Track state rulemaking, especially if operating across multiple jurisdictions.

OSHA Budget Cuts

The FY 2026 Department of Labor budget reflects reduced funding for OSHA, with cuts affecting staffing and compliance assistance programs, while pushing the agency to streamline enforcement activities rather than expand them. The result is a leaner OSHA that is prioritizing high-impact enforcement for Severe Injuries and Fatalities (SIFs) vs. routine inspections and prevention-first support. With reduced OSHA staff who are focused largely on high-profile case work, day‑to‑day guidance from OSHA will become harder to obtain, and there will be less capacity for outreach, training, and informal guidance.

Budget cuts reduce OSHA capacity, but not an organization’s liability. Standards, citation authority, and penalty structures remain intact, and enforcement still applies after incidents. SIFs will require prompt response from companies and appropriate documentation and records.

Tip: Strengthen internal investigations, recordkeeping practices and systems, and incident response readiness. Leverage relationships with third parties to fill in the gaps for safety support, training, and guidance.

OSHA Streamlined Rulemaking

Despite budget pressure, OSHA will continue to work on streamlined rulemaking to promote the following:

Heat Illness Prevention

Heat Stress legislation is anticipated in 2026, which will require employers to develop and implement a formal, written program that explains how heat hazards are identified, controlled, and managed.

Tip: Develop or update a Heat Illness and Injury Prevention Plan (HIIPP) to meet proposed regulatory requirements, including hazard assessments, high exposure tasks/locations, controls, acclimatization procedures, roles and responsibilities, training, incident response, and recordkeeping.

Workplace Violence Prevention

While no federal legislation is anticipated, civil unrest in areas around the country is causing many states to consider creating their own requirements for employers to help prevent workplace violence and protect workers from inside or outside attackers.

Tip: Evaluate your Emergency Action Plan and update it to reflect expectations for workers when dealing with workplace violence incidents. Include leadership commitment, clear policies and procedures, training, and continuous improvement.

Recordkeeping and Transparency

There is talk of more stringent data collection and public availability of that data for incidents. This is currently a big unknown given OSHA’s limited resources; however, there are indications of AI-enabled systems being introduced to support incident reporting, data analysis, and public data availability.

Tip: Data accuracy matters more than ever, as reporting errors themselves may become enforcement triggers. Implement and maintain systems to accurately collect, manage, and report incident data.

Others to Watch

PFAS “Forever Chemicals”. Per- and polyfluoroalkyl substances (PFAS) remain a focal point, as does the uncertainty surrounding, their regulation. There is currently a patchwork of federal requirements and state-level regulations and product bans in the U.S. The Federal government is on the path to making U.S. rules less stringent, while global restrictions are accelerating. Currently, the reporting period for manufacturers and importers of PFAS under the Toxic Substances Control Act (TSCA) will begin on April 13, 2026, with a final deadline for most by October 13, 2026. The EPA also has a pending rule to designate nine specific PFAS compounds as hazardous constituents under the Resource Conservation and Recovery Act (RCRA), requiring corrective action for their release. Federal PFAS legislation is unlikely; however, keep an eye on state regulations and other bills for any provisions associated with PFAS, particularly in industries such as textiles, cleaning products, cosmetics, and cookware.

Water Use. Water use is becoming a more significant EHS concern, particularly in western states, due to rising demand, increasing scarcity, and the environmental impacts associated with over-extraction (see Data Centers below). Desalinization plants and using non-potable water for industrial use, golf courses, etc. can create potentially very negative environmental impacts on entire ecosystems. Make sure your environmental audits every consider things like energy and water conservation. Monitor state regulations, particularly where scarcity is a concern. Incorporate water conservation into ESG strategies to elevate its importance.

Artificial Intelligence (AI). AI is everywhere, and EHS is not excluded. EPA and OSHA staffing shortages are accelerating interest in using AI for automation. And organizations are testing the limits on what AI can—and can’t—do effectively and correctly. The assumption that AI can be used to automate and manage EHS programs is a slippery slope. While AI can be leveraged as a tool for things like data aggregation and draft report development, using AI must be done thoughtfully, as it cannot replace EHS programs and human involvement. In fact, over‑automation without expert oversight can significantly increase error and legal exposure. Use caution exploring where you can use AI for more basic tasks that can be automated, as not all processes lend themselves to AI.

Data Centers. There has been an explosion of growth in data centers. This expansion is rapidly increasing demand for energy, driving more fossil fuel pollution, straining water resources, using agricultural land, creating noise pollution, and raising electricity prices across the country. This is of particular concern in parts of the Midwest, Texas, and Western states. At the federal level, there is currently limited direct regulation specific to data centers. Oversight typically occurs through state water withdrawal permits, air permits for generators, and local zoning and land‑use approvals. It is important to understand how the increase in data centers may impact ESG goals, particularly related to water, power, noise, and land use.

Looking Ahead

Organizations that treat 2026 as a moment to scale back EHS efforts risk being caught unprepared. Reduced federal activity does not equate to reduced liability. In fact, given the uncertainty, proactive, well-integrated EHS programs will be increasingly critical for protecting people, assets, and long-term enterprise value. Now is the time to:

- Reassess regulatory exposure, strengthen internal systems, and ensure EHS programs are resilient, auditable, and aligned with broader business and ESG objectives.

- Implement proactive planning, disciplined data management, and thoughtful use of technology to turn uncertainty into a competitive advantage.

- Leverage partnerships with consulting partners with deep regulatory insight and practical implementation experience to help navigate the evolving regulatory landscape, protect against emerging risks, and position your organization to sustain whatever the next regulatory cycle brings.

KTL to Present on Human Health Risk Assessments

KTL will be joining the technical program of the Society of Environmental Toxicology and Chemistry (SETAC) North America 46th Annual Meeting November 16-20, 2025 in Portland, Oregon. SETAC is dedicated to advancing environmental science and science-informed decision-making through collaboration, communication, eductaion, and leadership.

KTL Senior Associate Margaret Roy will be presenting Representation of the Homeless in Human Health Risk Assessment on Monday, November 17 at 10:00 am as part of Session 5.08: Beyond Direct Contact: Non-Traditional Exposure Scenarios in Human Health Risk Assessment.

Human Health Risk Assessments (HHRAs) are used to assess contaminant exposure and risk to defined populations, such as residents, commercial workers, and construction workers. HHRAs can also be used to assess risk for the homeless population. This presentation will discuss some of the challenges associated with developing an exposure model to represent the homeless sheltering and living on a contaminated site. For example, interviews with individuals may be necessary to develop an accurate exposure model. The presentation will also discuss the importance of the field sampling crew, from observing field conditions to safety concerns.

MECC 2025: KTL to Present on OSHA Fundamentals, IT Tools & EHS Challenges

KTL is excited to be joining the 2025 Midwest Environmental Compliance Conference (MECC) in Overland Park, Kansas, September 15-16, 2025, as a sponsor, presenter, and exhibitor. MECC takes a fresh, regional approach to the increasingly difficult task of environmental compliance, permitting, enforcement, and other critical environmental issues that impact Midwest facilities and institutions.

KTL will be leading the following sessions as part of the workshop’s technical agenda:

OSHA Fundamentals for Advancing Environmental Professionals

September 15, 2025 | 8:45 am | Presenter: April Greene, CSP, CHMM, Senior Consultant

Moving from environmental specialist to EHS leader means you suddenly need to know about fall protection, lockout/tagout, confined spaces, and more. This session gives environmental professionals the strategic safety overview on critical safety programs.

IT Tools for EHS Compliance: Demo

September 15, 2025 | 11:15 am | Presenter: Joseph Kunes, Consultant

Building an EHS IT system doesn’t have to be complicated or expensive. Most companies already

have the software they need. Learn how to build data management tools to collect, track, & report EHS

compliance information using the latest Microsoft 365 and Power Platform apps. See examples and

hear from EHS/IT experts on how you can benefit from this approach.

Navigating EHS Challenges in the Food Industry: Panel

September 16, 2025 | 9:40 am | Moderator: Joe Tell, Principal

In the fast-paced and highly regulated world of food production, EHS professionals play a critical role in maintaining operational excellence while protecting workers, consumers, and the environment. This panel brings together experienced EHS managers from across the food industry to share real-world insights, lessons learned, and practical strategies for overcoming today’s pressing EHS challenges. The session will offer takeaways to strengthen your EHS programs and drive continuous improvement.

And be sure to stop by and visit our booth in the exhibit hall. We look forward to seeing you at MECC!

KTL to Exhibit at the 155th Congress of Correction

KTL will be exhibiting at the American Correctional Association’s 155th Congress of Correction in Denver, CO, August 21-26, 2025. The Congress features a wide array of workshops and sessions focused on cutting-edge topics for correctional facilities. The educational workshops feature the best in the business, passing on critical knowledge and engaging in important discussions, while the expansive exhibit allows attendees to interact with hundreds of companies serving the correctional industry.

Be sure to stop by and visit KTL at Booth #871. We look forward to seeing you at the Congress of Correction!

The Business Case for Second-Party Audits

All types of organizations and operational processes demand a variety of audits and assessments to evaluate compliance with requirements—ranging from government regulations, to industry codes, to management system standards (e.g., ISO, GFSI), to internal obligations. Audits and assessments capture regulatory compliance status, management system conformance, supplier compliance, adequacy of internal controls, potential risks, and best practices.

Internal audits help identify problems so corrective/preventive actions can be put into place and then sustained and improved prior to third-party certification/compliance audits. Internal audits and assessments also help companies with continuous improvement initiatives.

Understanding the Internal Audit Process

Many organizations conduct internal audits with their own staff to assess conformance and identify opportunities for improvement. For companies large enough to have a dedicated internal audit team (with have no ties to the processes they audit), this may make perfect sense. However, it can take significant resources—time, personnel, money—to conduct all internal audits with internal resources.

It is easy to underestimate what goes into a successful audit and assume that it is more efficient and cost-effective to use internal resources. But that often isn’t the case. Let’s consider what an internal audit entails.

Pre-Audit Preparation

- Research: Auditors must understand the standard they are assessing against (i.e., regulatory, management systems, internal, industry). Effective auditors will also understand industry best practices; related local, state, and/or country-based requirements; processing norms for new product areas; etc. that can impact operational compliance and risks.

- Logistics: Logistics includes coordinating with the facility(ies) to schedule the audit and time with applicable personnel for interviews and, if travel is required, researching/booking flights, booking hotels, arranging for car transportation, etc.

- Document Review: Prior to the onsite audit, auditors should review available documentation (e.g., procedures, policies, programs). This will better inform and guide them on where they should dig more deeply during the audit, as well as help them create effective audit protocol (see below). Pre-audit document review also allows the onsite portion of the audit to remain focused on observing operations, interviewing workers, and verifying physical requirements are being met.

- Audit Protocol/Template: Auditors need to take the time to develop protocol/questions for conducting the audit, as well as standardized reporting templates, before the site visit. A standard protocol will make conducting multiple audits more efficient. Consistent protocols and templates also add value by allowing for direct year-over-year and site-to-site comparisons.

Onsite Audit

- Technical Knowledge: To efficiently conduct an audit, auditors must have a thorough understanding of the standard they are assessing against. In many cases, auditors are asked to juggle multiple areas of focus at once. For example, in a foods facility, the auditor may simultaneously evaluate Food and Drug Administration (FDA), U.S. Department of Agriculture (USDA), Global Food Safety Initiative (GFSI), and facility-specific procedure requirements. For an environmental, health, and safety (EHS) audit, the auditor may simultaneously assess Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), state agency, and facility-specific requirements. Deep technical knowledge of all the related standards and codes helps to ensure a thorough audit.

- Audit Tools: Having the right tool for the job can make audits significantly more efficient. This includes the audit protocol and templates developed as part of pre-audit preparation, as well as audit tools that may be used to conduct and manage audits more efficiently and effectively.

- Audit Management: Auditors are responsible for building a relationship of trust and openness with the facility quickly, while still maintaining control of the audit. This can be a challenge for internal auditors when interviewing colleagues and assessing internal systems.

Post-Audit Follow-up

- Report: Auditors need to synthesize observations from the audit to create a report that concisely conveys all pertinent information, including nonconformances with the defined standard(s). Auditors provide additional value when they can leverage their industry experience to prioritize findings and identify opportunities for improvement and best practices. Reports are most valuable when finalized within a few weeks of the site visit when information is fresh to facility staff.

- Corrective Actions: After an internal audit, facility staff will inevitably have questions regarding findings and what to do next. Auditors can provide valuable support by offering recommendations, building corrective action plans, and supplying technical guidance.

Many organizations do not have dedicated internal auditors—rather, internal auditing is an “add-on” responsibility—so time spent completing these internal audit activities takes time away from other business responsibilities. This often results in a post-audit period where the internal auditor has significant catchup to complete other work that has been put on the backburner while conducting the internal audit.

Value of a Second-Party Auditor

A second-party auditor can provide an objective assessment of overall compliance status and, in many cases, do it more efficiently than organizations are able to do with their own resources. A second-party auditor has the time required to conduct the audit, travel, review documents, and create a report. Beyond that, a second-party auditor also has audit tools and templates to create efficiencies when conducting the audit and reporting, can consolidate audit trips, and can spend dedicated time completing all audit activities as efficiently as possible without needing to factor in other business responsibilities.

Beyond saving significant resources, using a second party to conduct audits provides significant business value and additional return on investment:

- Objectivity: Enlisting a qualified outside firm to conduct an audit provides a fresh set of unbiased eyes to assess aspects of your program internal staff may not consider or see. Second-party auditors offer broad perspective and knowledge of best management practices from conducting audits across industries and standards. They maintain ongoing, up-to-date awareness of current and pending regulatory requirements that the organization should consider.

- Customizable: The audits themselves can be customized to fit the needs and goals of the organization. A second-party auditor can provide more direct coverage to evaluate specific program effectiveness and allow for a more focused understanding of existing strengths and improvement areas. Whether there is a desire to prepare for unannounced regulatory agency visits, review plans and programs, assess supplier compliance, or even verify applicability, second-party audits can be built to address the organization’s identified concerns and help manage risks.

- Effective Tools: Second-party auditors often bring effective audit tools to help conduct and manage audits. These tools capture regulatory compliance status and certification system conformance more efficiently, track audit progress/completion status by subject, and generate reports that can be used by management to inform decision making.

- Efficiency: Audits performed internally can take resources away from normal business operations not only when conducting the audit, but also when catching up on daily responsibilities and work that is set aside during the audit. Second-party auditors work with the resources allocated to them to conduct an audit in a timely manner that does not negatively impact business functions. These audits minimize the overall disruption in business compared to internal audits.

- Validation: Second-party auditors validate existing programs and identify areas where best practices can be implemented to further protect the company. They assist in identifying and prioritizing issues before they become violations—focusing on implementing and closing corrective actions. They also provide data and reports that can be shared internally with employees to improve performance or externally with communities or customers to bolster the company’s image.

- Consistency: Using the same second-party auditor to conduct your audits creates consistency across locations and over time. This allows the organization to establish a benchmark for performance that can be used to help ensure continuous improvement throughout the organization and its supply chain.

Second-party audits are not just about checking boxes—they are about building stronger partnerships, spotting issues early, and keeping your business running smoothly. Don’t wait for nonconformances to catch you off guard. Implementing second-party audits isn’t just a compliance tool, it is a strategic advantage.

Comments: No Comments

Is It Actually Empty?

Virtually every regulatory agency has regulations that require companies to fulfill very specific compliance requirements. Sometimes, there is overlap and businesses may be required to comply with similar—yet different—regulations from two different agencies. Using containers to store hazardous waste products is one of those tricky situations.

Different Definitions

Containers used for hazardous materials or waste are regulated under the Department of Transportation’s (DOT) Hazardous Materials Regulations (HMR) (49 CFR 173.29) and the Environmental Protection Agency’s (EPA) Resource Conservation and Recovery Act (RCRA) Hazardous Waste Requirements (40 CFR 261.7). The confusion between these rules comes in the definition of empty, which changes significantly from one agency to the next.

For both agencies, the definition of empty dictates how containers that once held hazardous waste and/or hazardous materials are managed (i.e., shipped and disposed of). However, a container can meet the criteria for emptiness according to EPA but still not be considered empty according to DOT for transportation purposes. It is important to understand the different definitions to be able to comply.

EPA RCRA-Empty

The EPA regulations regarding management of empty containers and residues establish procedures for determining if a container is empty (i.e., no longer contains hazardous waste) and defining when hazardous waste residue in an empty container is exempt from regulation. According to EPA, an empty chemical container has been removed of all materials or liquids via commonly employed practices (e.g., pumping, pouring, or aspirating). But what does this actually mean?

RCRA-empty conditions differ based on whether the container is holding non-acute hazardous waste, acute hazardous waste, or hazardous waste in compressed gas form, as shown in the table below.

| Waste Type | RCRA-Empty Conditions |

|---|---|

| Non-acute hazardous waste | 1. All wastes have been removed using commonly employed practices, and no more than 1 inch or residue remains; or 2. No more than 3% by weight of the container remains for containers < 119 gallons; or 3. No more than 0.3% by weight of the container remains for containers > 119 gallons. |

| Acute hazardous waste (P-listed wastes, other Code H hazardous wastes) | 1. Container is triple rinsed with material capable of removing acute waste; or 2. Container is cleaned by an alternate method that is scientifically proven to achieve equivalent waste removal; or 3. Inner liner that prevents contact between the container and waste is removed. |

| Compressed gases | The pressure within the container approaches atmospheric pressure. |

Containers that meet the definition of RCRA-empty are exempt from requiring specialized management as a hazardous waste. RCRA-empty containers can be disposed of at an authorized municipal solid waste landfill, recycled through a legitimate recycler, or reused onsite. Reuse requires properly emptying the container to avoid mixing incompatible substances that may create human health or environmental concerns. If a container is not found to be RCRA-empty, any residues removed from the container must be managed as hazardous waste under Subtitle C.

DOT Empty

DOT is responsible for hazardous materials shipping regulations. Unlike RCRA, DOT hazards are not defined by the quantity of material in the container; rather, the properties of the material dictate hazards. Even when a container appears empty, the hazardous material residue may still pose a hazard under the HMR. Per 49 CFR 173.29(a), these containers must follow the same rules as full hazmat containers when it comes to shipment. This includes having shipping papers, placards, labels, and markings, as well as providing training for employees who prepare the containers (full or empty) for shipping.

A container that once held hazardous materials is only considered exempt from HMR under the following conditions:

- The container remains unused.

- The container has been thoroughly cleaned and sufficiently purged of vapors to eliminate potential hazards.

- The container has been refilled with non-hazardous material to neutralize any remaining hazards from residue.

In addition, if the material inside the container is a DOT Class 9 material and meets the definition of RCRA-empty, the container is exempt from both EPA hazardous waste and DOT hazardous material shipping requirements.

Containers that meet the DOT criteria for being truly empty must have any hazard labels, markings, or placards that would be visible in transportation removed, covered, or obliterated to ensure emergency responders can correctly identify that the package contains no regulated hazardous materials.

Empty, Full, or Both?

In short, it is possible to have a container that EPA considers empty, but DOT does not. In this case, if you plan to ship the container, you would not have to follow any EPA hazardous waste rules, but DOT HMR would still apply when shipped.

A regulatory applicability assessment is a good first step in determining which regulations apply if you store hazardous waste in containers and/or plan to ship hazardous materials. If DOT’s HMR and EPA’s RCRA Hazardous Waste Requirements, it is then important to understand the distinction between the rules regarding what is considered empty to comply with both agency’s requirements.

Comments: No Comments

5 Tips to Become a Recycling Superstar

No single waste management strategy is suitable for managing all waste streams in all situations (Environmental Protection Agency (EPA)). As such, EPA’s non-hazardous materials and waste management hierarchy ranks the various waste management strategies from most to least environmentally preferred. Not surprisingly, the hierarchy emphasizes reducing and reusing—followed by recycling—as best practices for sustainable materials management, when possible.

While the best way to reduce waste is to never create it, recycling is a valuable way to collect used, reused, or unused items that would otherwise be considered waste and turn them into something valuable. From Fortune 500 companies to local businesses, to the restaurant on the corner—all have materials that can and should be recycled. The five tips below offer best practices for effectively managing your recycling efforts.

1. Conduct a trash audit.

A trash audit is a process in which an organization systematically analyzes and evaluates the contents of its waste, typically by sorting through the trash to identify the types and quantities of materials being discarded. This in-depth process provides a good baseline in developing a Recycling Program, as it helps to document the contents and quantity of your waste streams and then allows you to define how that waste gets managed.The audit helps to answer questions such as: What are you throwing away? How much is wasted food? Can you separate that out and send it to a composter? Can you stop making that trash? Can you reuse something? Can you sell it to someone else? Can you recycle it?

While not all trash can be reused or repurposed, it is consistent with EPA’s hierarchy to identify the materials produced that can be reused or repurposed as the first and most sustainable waste management solution (e.g., some tools can be sent back to the manufacturer to be refurbished and resold, or there may also be a “second life” outlet for materials). If materials are not able to be reused, the next best consideration is recycling.

2. Understand state and local regulations.

Once your trash audit identifies what items you want to recycle, it is important to consider the regulations. Different states and local governments may have specific requirements for the materials you want to recycle. For example, many states have compliance requirements for electronic wastes, used oil, or other universal wastes. In addition, EPA has very specific requirements for solid and hazardous waste recycling to ensure it is managed properly to avoid environmental and safety hazards. Engage experts, where necessary, if you have questions about certain materials that may have very specific or unclear requirements.

3. Implement a Recycling Program.

Based on the trash audit and regulatory requirements, a Recycling Program can be developed to serve as the roadmap for what gets recycled and how. The Recycling Program should clearly:

- Define what materials get recycled.

- Discuss proper disposal of materials, focusing on the most common items employees would handle in their day-to-day tasks.

- Identify collection points, so employees understand where to put items for recycling.

- Detail storage procedures for recyclable materials.

- Outline roles and responsibilities, including the parties responsible for recycling (see below).

- Provide for worker training to ensure the program is followed as intended.

- Reinforce the purpose of recycling and leadership’s commitment to the cause.

- Address how the program will be communicated to visitors, contractors, customers, shareholders, etc.

4. Partner with the right recyclers.

An important part of your Recycling Program is finding reputable recyclers who understand recycling regulations and are certified to handle the materials you are generating. This means working with recyclers who are transparent. Recyclers who are open about their practices are less likely to mishandle your recyclables than shady operators who could end up getting your company in a lot of trouble. Your recycler should help you identify the best ways to recycle your materials (e.g., setting up separate dumpsters for paper, plastic, food) and identify whether there are any cash-back opportunities for recycling certain materials (e.g., cardboard, scrap metal, electronic waste, etc.).

5. Maintain safe storage and handling practices.

As noted above, a trash audit will help you know what you are recycling. You also need to know how to properly store these materials while they are waiting to be recycled so they do not become a bigger hazard. For example, keep batteries for recycling in cool, dry places away from heat.

Conduct a proper risk assessment for the proposed storage spaces to capture and mitigate potential risks before finalizing your choice, document this in your Recycling Program, and then train employees on how to safely handle the material they are bringing to the recycling area. Precautions may include having the proper fire detection and suppression equipment for the area where you are storing material for recycling, or ensuring employees have the proper personal protective equipment (PPE) to wear when handling materials.

Creating a Recycling Culture

The above five tips can help ensure you have the systems, practices, programs, and partners in place to manage your trash and recycling. By following them, organizations can streamline their waste management processes, comply with environmental standards, and promote resource conservation and cost savings. But to truly become a “recycling superstar”, it is also important that you:

- Avoid all or nothing thinking—set realistic goals for what you can accomplish while still complying with regulations.

- Implement robust quality control processes to avoid making mistakes.

- Think creatively about how your team can work together reduce, reuse, repurpose and recycle your trash and get closer to zero waste.

- Measure your results. Conduct your trash audits annually to assess what is working and what is not and then set new goals to continually improve.

Effective waste management and recycling are essential for organizations striving to operate sustainably and reduce their environmental impacts. Ultimately, fostering a culture of creativity, continuous improvement, and accountability will lead organizations closer to their zero-waste goals, benefiting the environment and the bottom line.

Comments: No Comments

EHS: Top Trends for 2025

Every year, we see a number of environmental, health, and safety (EHS) trends rise to the surface that have the potential to impact many industries. As we enter 2025, some challenges and opportunities in EHS remain ongoing; some are just gaining traction with impacts yet to be known, particularly with a change in Administration just taking hold. Here are some of the top EHS trends KTL is keeping watch on in 2025…

Regulatory Landscape

In 2022, the Environmental Protection Agency (EPA) published its FY 2022-2026 EPA Strategic Plan to communicate the Agency’s vision, priorities, and strategies. Specifically, the Plan includes targeted objectives and outcomes in the areas of climate change; environmental justice; compliance enforcement; clean land, air, and water; and chemical safety. The Occupational Safety and Health Administration’s (OSHA’s) focus centers on National Emphasis Programs (NEPs) for 2025 related to combustible dust, fall protection/prevention, heat, silica crystalline, and warehousing and distribution center operations, as well as many regional directives.

With a new Administration taking office in January, a big unknown of the coming four years is how the EHS regulatory landscape will change. There is speculation regarding plans to reorganize the EPA and establish “pause and review” teams to assess major rules, guidance materials, grants, legal settlements, budgets, etc. How this will translate into regulatory action remains to be seen.

Update: According to InsideEPA.com, acting EPA Administrator James Payne issued a directive on January 24, 2025, ordering all EPA staff to stop all communications with external parties pending further instruction. Exemptions will allow EPA staff to continue to communicate with state and federal agencies, provided they do not discuss enforcement matters; talk to relevant partieis to facilitate imports; and continue conducting inspections. It is unclear at this time how long the directive will remain in place.

Mental Health

Companies are increasingly recognizing that traditional safety programs must evolve to prioritize mental health as much as physical health—from mental health days to employee assistance programs, to stress management training, to flexible work hours. Correspondingly, psychological safety is becoming a critical concept for building effective teams and encouraging workplace innovation and success. A psychologically safe culture allows employees to take reasonable risks in a safe environment without negative interpersonal consequences.

A related concept is safety culture, which is concerned with many cognitive aspects of safety, like norms, perceptions, beliefs, and values. Emphasizing mental health as part of the organization’s safety culture may become a priority for mature organizations. As the concept of total worker health continues to expand, the focus on mental health is also likely to be reinforced by new regulations and standards regarding psychological safety in the workplace.

Sustainability and Climate Change

Environmental, Social, and Governance (ESG) initiatives have dominated many corporate agendas for the past several years, particularly with Europe and Canada advancing standards related to sustainability and climate change data reporting and ISO’s recent Climate Change Amendments. Many organizations have worked to significantly improve their data collection efforts and have integrated climate change management and circular economy principles into their sustainability strategies.

The change in Administration may increase scrutiny regarding the value of these ESG initiatives. We have already seen the Securities and Exchange Commission’s (SEC) March 2024 Climate-Related Disclosures Rule stayed due to multiple petitions and lawsuits. This may be a sign of things to come. Many companies have invested in their ESG efforts and will continue to do so, but 2025 may present an opportunity to reassess and streamline initiatives to ensure they are practical and upholding sustainability goals, while also contributing value to the company.

PFAS

Per- and polyfluoroalkyl substances (PFAS) became a focal point for EPA in 2021 with the publication of its PFAS Strategic Roadmap, which committed to addressing concerns related to PFAS exposure. Actions have included improving reporting on PFAS, as well as adding seven additional PFAS to the Toxics Release Inventory (TRI) in January 2024 and an additional nine in January 2025. In April 2024, EPA announced three more notable actions, including introducing the first-ever national drinking water standards and designating perfluorooctanoic acid (PFOA) and perfluorooctane sulfonic acid (PFOS) as “hazardous substances” under Superfund. In addition, the updated Interim Guidance on the Destruction and Disposal of PFAS and Materials Containing PFAS will require entities to report releases of these “forever pollutants” that exceed threshold quantities.

Beyond federal regulations, many states are introducing policies related to PFAS, including monitoring and testing for PFAS in water and sewage sludge and banning PFAS in food packaging, clothing, and other consumer products. Organizations need to address PFAS in their operations, products, supply chains, and waste streams; stay informed about ongoing PFAS regulatory developments; and adjust compliance programs and operational practices, as needed.

Personal Protective Equipment (PPE)

Properly fitting PPE is essential for workers to complete their tasks safely. If PPE is not correctly fitted to the body, it can cause discomfort and increase the risk of workplace accidents and injuries. On December 11, 2024, the Occupational Safety and Health Administration (OSHA) announced its finalized revision to the PPE Standard for Construction, which requires PPE to properly fit any construction worker who needs it, including women and physically smaller or larger workers.

Employers must ensure that every employee not only has the right PPE, but that it also fits. Fit testing may identify the need for PPE alternatives to meet the anthropometric needs of all workers. Importantly, employees must be trained and empowered to speak up if PPE does not fit appropriately to ensure their safety.

Technology/AI

Artificial intelligence (AI) and machine learning technologies have the capacity to significantly alter how companies manage their EHS programs. While still not fully mature, these technologies are becoming more sophisticated. As AI evolves and becomes more generally accepted, more companies are likely to start adopting it to automate routine compliance tasks, conduct EHS assessments, perform training simulations, predict potential safety incidents, monitor workplace conditions in real-time, and more.

While the efficiencies and other benefits of technology solutions are many, the increased reliance on AI and machine learning will require increased oversight and management. In particular, companies will need to determine where automation is appropriate and where the human factor is still required. Not all processes lend themselves to AI. It will also be imperative to consider stronger data privacy protocols to ensure the security of the company.

Others to Watch

- OSHA Reporting: On January 1, 2024, the Department of Labor’s (DOL’s) final rule requiring employers in designated high-hazard industries to electronically submit injury and illness information to OSHA took effect. KTL inspections routinely find errors and omissions in OSHA recordkeeping. Effective solutions, particularly areas where hard copies can be replaced by digital forms, are needed.

- Hazard Communication Standard: The final Hazard Communication Standard took effect on July 19, 2024, implementing the first major updates since 2012. The first compliance date requires chemical manufacturers, importers, and distributors to update labels and Safety Data Sheets (SDSs) for chemical substances by July 19, 2026.

- Lead Levels: In January 2024, the EPA reduced the acceptable amount of lead in soil for residential exposure, stating that no level of lead is acceptable. These reduced levels may soon be translated into commercial exposures.

- One Health: Both the Society of Environmental Toxicology and Chemistry (SETAC) and Society of Toxicology (SOT) have adopted One Health initiatives as an integrated, unifying approach that aims to sustainably balance and optimize the health of people, animals, and ecosystems (SOT). The idea is to look at the health of our environment and all aspects of our environment as a whole and not one component at a time. This idea is being translated into health impact assessments.

- Pesticide/Herbicide Re-evaluation: The EPA has initiated re-evaluations of registered pesticides, herbicides, rodenticides, and fungicides, including the highly publicized Roundup. These reviews are expected to result in a recommendation to focus the use of these chemicals rather than using a general broadcast application.

- Microplastics: Microplastics have been found in every ecosystem on the planet—in food, beverages, and human and animal tissue. Scientists do not fully understand the impacts of microplastics on human health and aquatic life, and industry is struggling with how to manage them due to their pervasive nature and wide variety of shapes and sizes. Ongoing research in pollution prevention will be forthcoming.

Getting Ahead in 2025

In 2025, organizations will continue to encounter evolving workplace challenges, regulatory adjustments, societal demands, economic pressures, and rapid advancements in technology—some of which can be anticipated, some which remain to be seen. KTL suggests completing the following early in 2025 to prepare for whatever is on the horizon:

- Get senior leadership commitment. Even with the best EHS personnel, the organization and its EHS system will only be as strong as the top leadership and what they prioritize.

- Stay abreast of regulatory developments. Monitor what is going on at the federal (i.e., EPA and OSHA) and state levels, assess your regulatory applicability, and evaluate how any potential regulatory changes over the next year(s) may impact your operations.

- Conduct a comprehensive gap assessment to ensure you are efficiently meeting your EHS requirements (i.e., regulatory, management systems, internal, supply chain). Think critically about how overlapping requirements may apply (e.g., your chemical inventory may uncover requirements for air permitting, waste management, Tier II report, etc.) and how you can integrate systems to improve efficiency and compliance.

- Determine where you can integrate technology solutions into your operations. This could mean stepping into the world of AI and machine learning; it could also mean implementing compliance information management systems to help manage compliance and reporting requirements. Technology advancements can help create significant business efficiencies when used appropriately.

- Seek third-party oversight. Many EHS departments are severely understaffed. Having external experts periodically look inside your company provides an objective view of operations, helps you to prepare for audits, and allows you to implement corrective/preventive actions that ensure compliance. An outside expert can often provide the “big picture” view of what you have vs. what you need; how your plans, programs, and requirements intersect; and how you can best comply with changing requirements.

KTL to Join the Technical Program of the SETAC Annual Meeting

KTL will be joining the technical program of the Society of Environmental Toxicology and Chemistry (SETAC) North America 45th Annual Meeting October 20-24, 2024 in Forth Worth, TX. SETAC is dedicated to advancing environmental science and science-informed decision-making through collaboration, communication, eductaion, and leadership.

KTL Senior Consultant Margaret Roy will be co-chairing Session 6.04.T – Risk Assessment, Remediation, and Restoration: Applying Interdisciplinary Approaches to Creating Successful Remediation and Restoration Projects on Wednesday, October 23 from 10:00am – 12:00pm.

In addition, KTL is co-author to the following poster, which will be on exhibit all day on Monday, October 21:

Human Health and Ecological Risk Assessment of the Herbicide Flumioxazin for the U.S. Forest Service

5.12.P-Mo-160 | Presenters: Julie Rothrock, SRC, Inc.; Margaret Roy, KTL; and Dan Tekiela, U.S. Forest Service

The United States Department of Agriculture (USDA) Forest Service (FS) is responsible for protecting and managing natural resources on National Forest System lands. Pesticides are one tool used by the FS to prevent, control, or manage forest insects, diseases, and invasive plants. When considering the use of a pesticide on forest lands, the FS conducts a human health and ecological risk assessment (HHERA) to evaluate risk to FS personnel, the public, and the environment, and to then make decisions regarding specific applications of pesticides on forest lands throughout the U.S. This poster presentation outlines the process for conducting theHHERA for the herbicide flumioxazin to estimate the nature and degree of potential risks, both human health and environmental, associated with its use in FS vegetation management programs.